Page 77 - Chemical Process Equipment - Selection and Design

P. 77

3.3. EQUIPMENT CONTROL 49

m

alternate location

STM

PRODUCT

(a) I-

PRODUCT

PRODUCT

---+---

(e) CONDENSATE i CONDENSATE

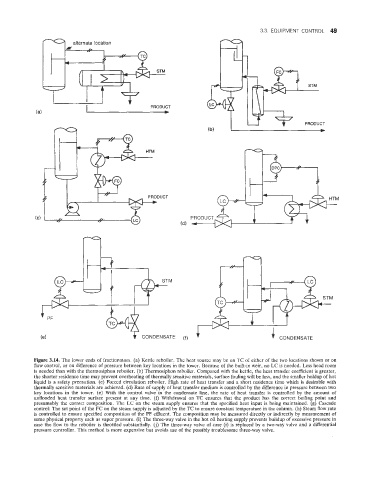

Figure 3.14. The lower ends of fractionators. (a) Kettle reboiler. The heat source may be on TC of either of the two locations shown or on

flow control, or on difference of pressure between key locations in the tower. Because of the built-in weir, no LC is needed. Less head room

is needed than with the thermosiphon reboiler. (b) Thermosiphon reboiler. Compared with the kettle, the heat transfer coefficient is greater,

the shorter residence time may prevent overheating of thermally sensitive materials, surface fouling will be less, and the smaller holdup of hot

liquid is a safety precaution. (c) Forced circulation reboiler. High rate of heat transfer and a short residence time which is desirable with

thermally sensitive materials are achieved. (d) Rate of supply of heat transfer medium is controlled by the difference in pressure between two

key locations in the tower. (e) With the control valve in the condensate line, the rate of heat transfer is controlled by the amount of

unflooded heat transfer surface present at any time. (f) Withdrawal on TC ensures that the product has the correct boiling point and

presumably ,the correct composition. The LC on the steam supply ensures that the specified heat input is being maintained. (9) Cascade

comtrol: The set point of the FC on the steam supply is adjusted by the TC to ensure constant temperature in the column. (h) Steam flow rate

is controlled to ensure specified composition of the PF effluent. The composition may be measured directly or indirectly by measurement of

some physical property such as vapor pressure. (i) The three-way valve in the hot oil heating supply prevents buildup of excessive pressure in

case the flow to the reboiler is throttled substantially. (j) The three-way valve of case (i) is replaced by a two-way valve and a differential

pressure controller. This method is more expensive but avoids use of the possibly troublesome three-way valve.