Page 82 - Chemical Process Equipment - Selection and Design

P. 82

54 PROCESS CONTROL

(a) Stirred tanks are used either as batch or continuous flow

Feed reactors. Heat transfer may be provided with an external heat

b exchanger, as shown on this figure, or through internal surface

or a jacket. Alternate modes of control may be used with the

controls shown: (i) When the HTM is on temperature control,

the pumparound will be on flow control; (ii) when the

pumparound is on temperature control, the HTM will be on

Flow flow control; (iii) for continuous overflow of product, the

Ratio control point for temperature may be on that line or in the

Control vessel; (iv) for batch operation, the control point for

temperature clearly must be in the vessel. Although level

control is shown to be maintained with an internal weir, the

product can be taken off with the pump on level control.

(b) This shows either direct or cascade control of the temperature

of a reactor with internal heat transfer surface and an internal

c weir. The sluggishly responding temperature of the vessel is

(a) Solvent - used to reset the temperature controuer of the HTM. For direct

control, the TC-2 is omitted and the control point can be on the

2 gases to be drawn off directly, thus eliminating need for the

HTM outlet or the product line or in the vessel.

the contents are boiling. The sketch shows temperature

-I---

maintenance by refluxing evolved vapors. A drum is shown

Raffinate € (e) Quite a uniform temperature can be maintained in a reactor if

from which uncondensed gases are drawn off on pressure

control, but the construction of the condenser may permit these

drum. The HTM of the condenser is on TC which resets the

PC if necessary in order to maintain the correct boiling

Reset

temperature in the reactor. Other modes of pressure control

are shown with the fractionator sketches of Figure 3.15 and on

Figure 3.5 dealing with vacuum control.

Ida (a) Flow reactors without mechanical agitation are of many

configurations, tanks or tubes, empty or containing fixed beds

Solvent of particles or moving particles. When the thermal effects of

reaction are substantial, multiple small tubes in parallel are

1 m used to provide adequate heat transfer surface. The sketch

shows a single tube provided with a jacket for heat transfer.

Feed to the reactor is on flow control, the effluent on pressure

control, and the flow of the HTM on temperature control of the

effluent with the possibility of reset by the composition of the

effluent.

(e) Heat transfer to high temperature reactions, above 300°C or so,

-m may be accomplished by direct contact with combustion gases.

The reaction tubes are in the combustion zone but safely away

from contact with the flame. The control mode is essentially

HTM similar to that for case (d), except that fuel-air mixture takes

the place of the HTM. The supply of fuel is on either

(C)

temperature or composition control off the effluent stream, and

the air is maintained in constant ratio with the fuel with the

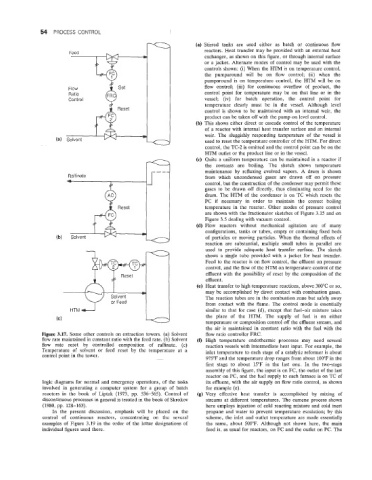

Figure 3.17. Some other controls on extraction towers. (a) Solvent flow ratio controller FRC.

flow rate maintained in constant ratio with the feed rate. (b) Solvent (fJ High temperature endothermic processes may need several

flow rate reset by controlled composition of raffinate. (c) reaction vessels with intermediate heat input. For example, the

Temperature of solvent or feed reset by the temperature at a inlet temperature to each stage of a catalytic reformer is about

control point in the tower.

975°F and the temperature drop ranges from about 100°F in the

first stage to about 15°F in the last one. In the two-stage

assembly of this figure, the input is on FC, the outlet of the last

reactor on PC, and the fuel supply to each furnace is on TC of

logic diagrams for normal and emergency operations, of the tasks its effluent, with the air supply on flow ratio control, as shown

involved in generating a computer system for a group of batch for example (e).

reactors in the book of Liptak (1973, pp. 536-565). Control of (g) Very effective heat transfer is accomplished by mixing of

discontinuous processes in general is treated in the book of Skrokov streams at different temperatures. The cumene process shown

(1980, pp. 128-163). here employs injection of cold reacting mixture and cold inert

In the present discussion, emphasis will be placed on the propane and water to prevent temperature escalation; by this

control of continuous reactors, concentrating on the several scheme, the inlet and outlet temperature are made essentially

examples of Figure 3.19 in the order of the letter designations of the same, about 500°F. Although not shown here, the main

individual figures used there. feed is, as usual for reactors, on FC and the outlet on PC. The