Page 86 - Chemical Process Equipment - Selection and Design

P. 86

58 PROCESS CONTROL

W

Separator

Reactor *

Liquid

Water

-_

:$ Stripper - -

Stripping

Steam

Reactor

\ I Air Preheater Steam

Oil Charge at

Controlled Temperature

Regenerator Air

Figure 3.19-(continued)

Flow Rate, gpm

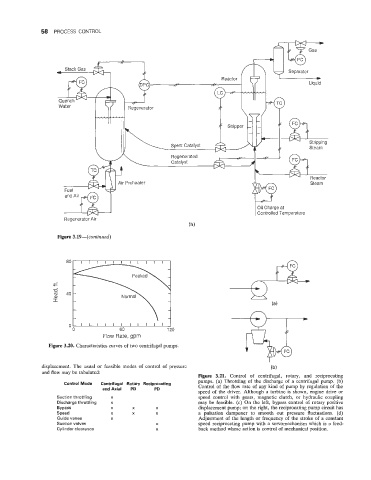

Figure 3.20. Characteristics curves of two centrifugal pumps.

displacement. The usual or feasible modes of control of pressure

and flow may be tabulated:

Figure 3.21. Control of centrifugal, rotary, and reciprocating

pumps. (a) Throttling of the discharge of a centrifugal pump. (b)

Control Mode Centrifugal Rotary Reciprocating

andhiat PD PD Control of the flow rate of any kind of pump by regulation of the

speed of the driver. Although a turbine is shown, engine drive or

Suction throttling X speed control with gears, magnetic clutch, or hydraulic coupling

Discharge throttling x may be feasible. (c) On the left, bypass control of rotary positive

Bypass X X X displacement pump; on the right, the reciprocating pump circuit has

Speed X X X a pulsation dampener to smooth out pressure fluctuations. (d)

Guide vanes X Adjustment of the length or frequency of the stroke of a constant

Suction valves X speed reciprocating pump with a servomechanism which is a feed-

Cylinder clearance X back method whose action is control of mechanical position.