Page 81 - Chemical Process Equipment - Selection and Design

P. 81

3.3. EQUIPMENT CONTROL 53

r--l

Solvent

Extract Raffinate

(a)

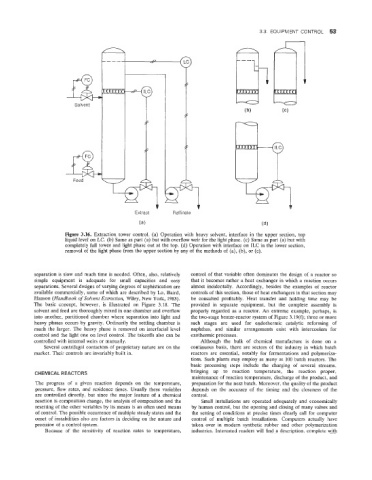

Figure 3.16. Extraction tower control. (a) Operation with heavy solvent, interface in the upper section, top

liquid level on LC. (b) Same as part (a) but with overflow weir for the light phase. (c) Same as part (a) but with

completcly full tower and light phase out at the top. (d) Operation with interface on ILC in the lower section,

removal of the light phase from the upper section by any of the methods of (a), (b), or (c).

separation is slow and much time is needed. Often, also, relatively control of that variable often dominates the design of a reactor so

simple equipment is adequate for small capacities and easy that it becomes rather a heat exchanger in which a reaction occurs

separations. Several designs of varying degrees of sophistication are almost incidentally. Accordingly, besides the examples of reactor

available commercially, some of which are described by Lo, Baird, controls of this section, those of heat exchangers in that section may

Nanson (Hundbook of Solvent Exiracfion, Wiley, New York, 1983). be consulted profitably. Heat transfer and holding time may be

The basic concept, however, is illustrated on Figure 3.18. The provided in separate equipment, but the complete assembly is

solvent and feed are thoroughly mixed in one chamber and overflow properly regardled as a reactor. An extreme example, perhaps, is

into another, partitioned chamber where separation into light and the two-stage heater-reactor system of Figure 3.19(f); three or more

heavy phases occurs by gravity. Ordinarily the settling chamber is such stages are used for endothermic catalytic reforming of

much the larger. The heavy phase is removed on interfacial level naphthas, and similar arrangements exist with intercoolers for

control and the light one on level control. The takeoffs also can be exothermic processes.

controlled with internal weirs or manually. Although the bulk of chemical manufacture is done on a

Several centrifugal contactors of pIoprietary nature are on the continuous basis, there are sectors of the industry in which batch

market. Their controls arc invariably built in. reactors are essential, notably for fermentations and polymeriza-

tions. Such plants may employ as many as 100 batch reactors. The

basic processing steps include the charging of several streams,

CHEMICAL REACTORS bringing up to reaction temperature, the reaction proper,

maintenance of reaction temperature, discharge of the product, and

Th~he progress of a given reaction depends on the temperature, preparation for the next batch. Moreover, the quality of the product

pressure, flow rates, and residence times. Usually these variables depends on the accuracy of the timing and the closeness of the

are controlled directly, but since the major feature of a chemical control.

reaction is composition change, the analysis of composition and the Small installations are operated adequately and economically

resetting of the other variables by its means is an often used means by human control, but the opening and closing of many valves and

of control. The possible occurrence of multiple steady states and the the setting of conditions at precise times clearly call for computer

onset of instabilities also are factors in deciding on the nature and control of multiple batch installations. Computers actually have

precision of a control system. taken over in modern synthetic rubber and other polymerization

Because of the sensitivity of reaction rates to temperature, industries. Interested readers will find a description, complete with