Page 75 - Chemical Process Equipment - Selection and Design

P. 75

3.3. EQUIPMENT CONTROL

DISTILLATION EQUIPMENT

As a minimum, a distillation assembly consists of a tower, reboiler,

condenser, and overhead accumulator. The bottom of the tower

serves as accumulator for the bottoms product. The assembly must

be controlled as a whole. Almost invariably, the pressure at either

the top or bottom is maintained constant; at the top at such a value

that the necessary reflux can be condensed with the available

coolant; at the bottom in order to keep the boiling temperature low

enough to prevent product degradation or low enough for the

available HTM, and definitely well below the critical pressure of the

bottom composition. There still remain a relatively large number of

variables so that care must be taken to avoid overspecifying the

number and kinds of controls. For instance, it is not possible to

control the flow rates of the feed and the top and bottom products

under perturbed conditions without upsetting holdup in the system.

Two flowsketches are shown on Figures 3.1 and 3.12 of controls

on an ethylene fractionator. On Figure 3.1, which is part of the

- + TRAP complete process of Figure 3.2, a feedforward control system with a

PF LIQUID

multiplicity of composition analyzers is used to ensure the high

degree of purity that is needed for this product. The simpler

PF VAPOR diagram, Figure 3.12, is more nearly typical of two-product

-----c

fractionators, the only uncommon variation being the use of a

feed-overhead effluent heat exchanger to recover some refrig-

eration.

Crude oil fractionators are an example of a more elaborate

system. They make several products as side streams and usually

have some pumparound reflux in addition to top reflux which serve

to optimize the diameter of the tower. Figure 3.13 is of such a tower

operating under vacuum in order to keep the temperature below

~ --..- cracking conditions. The side streams, particularly those drawn off

___"__

I atmospheric towers, often are steam stripped in external towers

I

hooked up to the main tower in order to remove lighter com-

ponents. These strippers each have four or five trays, operate

OVHD PRODUCT

REFRIGERANT

c

(d) COLD PF

Figure 3.11. Vaporizers (reboilers). (a) Vaporizer with flow-rate of

HTM controlled by temperature of the PF vapor. HTM may be

liquid or vapor to start. (b) Thermosiphon reboiler. A constant rate

of heat input is assured by flow control of the HTM which may be

either liquid or vapor to1 start. (c) Cascade control of vaporizer. The

flow control on the WTlM supply responds rapidly to changes in the

heat supply system. The more sluggish TC on the PF vapor resets

the FC if need be io maintain temperature. (d) Vaporization of

refrigerant and cooling of process fluid. Flow rate of the PF is the FEED REFLUX PUMP

primary control. The flow rate of refrigerant vapor is controlled by

the level in the drum to ensure constant condensation when the

incoming PF is in vapor form.

transfer processes the object is to control the final temperature of

the process fluid (PF) or the pressure of its source or to ensure a t

constant rate of heat input. This is accomplished primarily by

regulation of the flow of the heat transfer medium (HTM). BTMS PRODUCT

Regulation of the temperature of the HTM usually is less I m

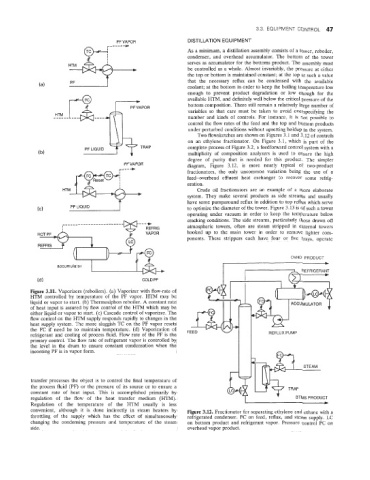

convenient, although it is done indirectly in steam heaters by Figure 3.12. Fractionator for separating ethylene and ethane with a

throttling of the suppiy which has the effect of simultaneously refrigerated condenser. FC on feed, reflux, and steam supply. LC

changing the condensing pressure and temperature of the steam on bottom product and refrigerant vapor. Pressure control PC on

side. overhead vapor product.