Page 74 - Chemical Process Equipment - Selection and Design

P. 74

46 PROCESS CONTROL

PF VAPOR

-__-------

(a) =fry+

STM

___

P PF CONDENSATE

steam trap or

liquid level controller

PF VAPOR

(b) + PF CONDENSATE

4 PF CONDENSATE

(C)

accumulator drum

HTM 10-15 FT

PF CONDENSATE

(d) i

~7 trap

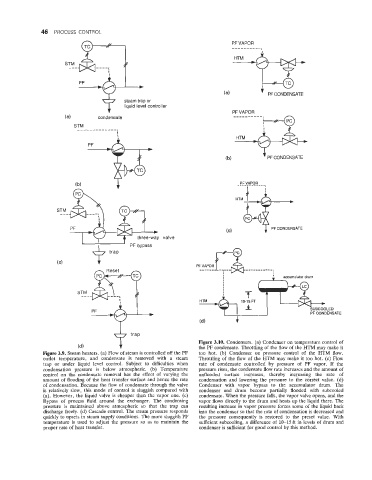

Figure 3.10. Condensers. (a) Condenser on temperature control of

the PF condensate. Throttling of the flow of the HTM may make it

too hot. (b) Condenser on pressure control of the HTM flow.

Throttling of the flow of the HTM may make it too hot. (c) Flow

rate of condensate controlled by pressure of PF vapor. If the

pressure rises, the condensate flow rate increases and the amount of

unflooded surface increases, thereby increasing the rate of

condensation and lowering the pressure to the correct value. (d)

Condenser with vapor bypass to the accumulator drum. The

condenser and drum become partially flooded with subcooled

condensate. When the pressure falls, the vapor valve opens, and the

vapor flows directly to the drum and heats up the liquid there. The

resulting increase in vapor pressure forces some of the liquid back

into the condenser so that the rate of condensation is decreased and

the pressure consequently is restored to the preset value. With

sufficient subcooling, a difference of 10-15 ft in levels of drum and

condenser is sufficient for good control by this method.