Page 73 - Chemical Process Equipment - Selection and Design

P. 73

3.3. EQUIPMENT CONTROL 45

(a)

HTM

Adjustable Adjustable

Collar

(d)

Weight Sensing

Fgwe 3.7. Solids feeders with variable speed drives. (a) Rotary Y ‘VALVE

vane (star) feeder with variable speed drive. (b) Horizontal screw

feeder. (c) Belt feeder taking material frlom a bin with an adjustable

underflow weir. (d) Rotary plate feeder: Rate of discharge is I I

controlled by the rotation speed, height of the collar, and the WTM

position of the plow. (e) Continuously weighing feeder with variable

speed belt conveyor.

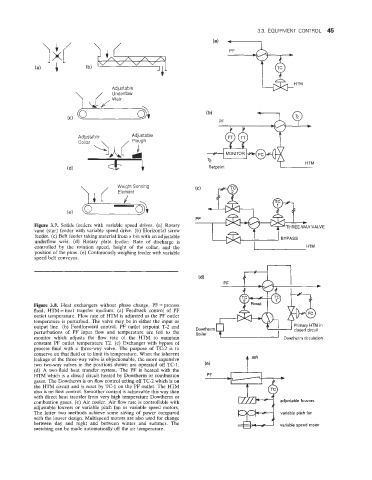

Figure 3.8. Heat exchangers without phase change. PF = process

fluid, HTM = heat transfer medium. (a) Feedback control of PF

outlet temperature. Flow rate of HTM is adjusted as the PF outlet

temperature is perturbed. The valve may be in either the input or

output line. (b) Feedforward control. IPF outlet setpoint T-2 and

perturbations of PF input flow and temperature are fed to the Dowthei

Boiler

monitor which adjusts the flow rate of the HTM to maintain I ’ Dowtherm circulation

constant PF outlet temperature T2. (c) Exchanger with bypass of

process fluid with a three-way valve. ‘The purpose of TC-2 is to

conserve on that fluid or to limit its temperature. When the inherent

leakage of the three-way valve is objectionable, the more expensive

two two-way valves in the positions shown are operated off TC-1.

(d) A two-fluid heat transfer system. The PF is heated with the

HTM which is a closeld circuit heated by Dowtherm or combustion

gases. The Dowtherm is on flow control acting off TC-2 which is on

the HTM circuit and is reset by TC-1 on the PF outlet. The HTM

also is on flour control. Smoother control is achievable this way than

with direct heat transfer from very high temperature Dowtherm or

combustion gases. (e) Air cooler. Air flow rate is controllable with adjustable louvers

adjustable lowers or variable pitch fan or variable speed motors.

The latter two methods achieve some saving of power compared variable pitch fan

with the louver design. Multispeed motors are also used for change

between day and night and between winter and summer. The variable speed motor

switching can be made automatically off the air temperature.