Page 102 - Chemical and process design handbook

P. 102

Speight_Part II_A 11/7/01 3:16 PM Page 2.43

ALUMINA 2.43

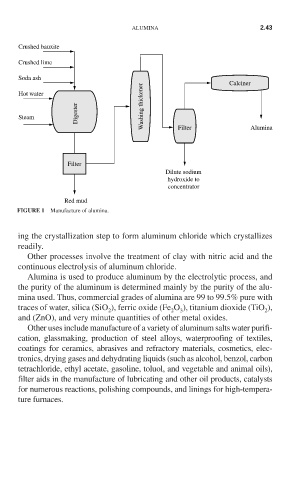

Crushed bauxite

Crushed lime

Soda ash

Calciner

Hot water

Digester Washing thickener

Steam Filter Alumina

Filter

Dilute sodium

hydroxide to

concentrator

Red mud

FIGURE 1 Manufacture of alumina.

ing the crystallization step to form aluminum chloride which crystallizes

readily.

Other processes involve the treatment of clay with nitric acid and the

continuous electrolysis of aluminum chloride.

Alumina is used to produce aluminum by the electrolytic process, and

the purity of the aluminum is determined mainly by the purity of the alu-

mina used. Thus, commercial grades of alumina are 99 to 99.5% pure with

traces of water, silica (SiO ), ferric oxide (Fe O ), titanium dioxide (TiO ),

2

2

2

3

and (ZnO), and very minute quantities of other metal oxides.

Other uses include manufacture of a variety of aluminum salts water purifi-

cation, glassmaking, production of steel alloys, waterproofing of textiles,

coatings for ceramics, abrasives and refractory materials, cosmetics, elec-

tronics, drying gases and dehydrating liquids (such as alcohol, benzol, carbon

tetrachloride, ethyl acetate, gasoline, toluol, and vegetable and animal oils),

filter aids in the manufacture of lubricating and other oil products, catalysts

for numerous reactions, polishing compounds, and linings for high-tempera-

ture furnaces.