Page 199 - Chemical engineering design

P. 199

176

CHEMICAL ENGINEERING

4.6.2. Illustration of the method

The procedure for setting up the equations and assigning suitable values to the split-

fraction coefficients is best illustrated by considering a short problem: the manufacture of

acetone from isopropyl alcohol.

Process description

heat

Reaction: C 3 H 7 OH ! CH 3 2 CO C H 2

cat.

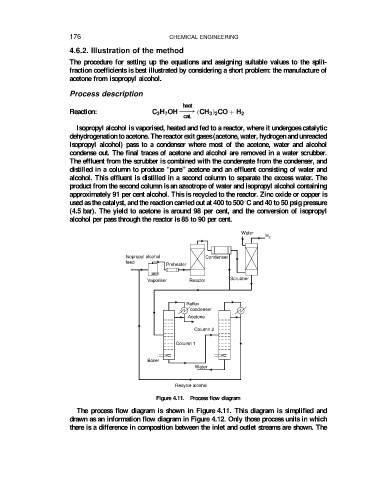

Isopropyl alcohol is vaporised, heated and fed to a reactor, where it undergoes catalytic

dehydrogenation to acetone. The reactor exit gases (acetone, water, hydrogen and unreacted

isopropyl alcohol) pass to a condenser where most of the acetone, water and alcohol

condense out. The final traces of acetone and alcohol are removed in a water scrubber.

The effluent from the scrubber is combined with the condensate from the condenser, and

distilled in a column to produce “pure” acetone and an effluent consisting of water and

alcohol. This effluent is distilled in a second column to separate the excess water. The

product from the second column is an azeotrope of water and isopropyl alcohol containing

approximately 91 per cent alcohol. This is recycled to the reactor. Zinc oxide or copper is

Ž

used as the catalyst, and the reaction carried out at 400 to 500 C and 40 to 50 psig pressure

(4.5 bar). The yield to acetone is around 98 per cent, and the conversion of isopropyl

alcohol per pass through the reactor is 85 to 90 per cent.

Water

H 2

Isopropyl alcohol Condenser

feed

Preheater

Vaporiser Reactor Scrubber

Reflux

condenser

Acetone

Column 2

Column 1

Boiler

Water

Recycle alcohol

Figure 4.11. Process flow diagram

The process flow diagram is shown in Figure 4.11. This diagram is simplified and

drawn as an information flow diagram in Figure 4.12. Only those process units in which

there is a difference in composition between the inlet and outlet streams are shown. The