Page 200 - Chemical engineering design

P. 200

FLOW-SHEETING

H

Alcohol feed

product

vent Water Acetone Water 177

Reactor Condenser Scrubber Coln 1 Coln 2

1 2 3 4 5

Bypass

Recycle

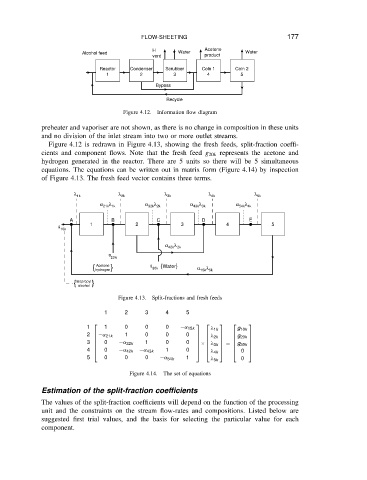

Figure 4.12. Information flow diagram

preheater and vaporiser are not shown, as there is no change in composition in these units

and no division of the inlet stream into two or more outlet streams.

Figure 4.12 is redrawn in Figure 4.13, showing the fresh feeds, split-fraction coeffi-

cients and component flows. Note that the fresh feed g 20k represents the acetone and

hydrogen generated in the reactor. There are 5 units so there will be 5 simultaneous

equations. The equations can be written out in matrix form (Figure 4.14) by inspection

of Figure 4.13. The fresh feed vector contains three terms.

λ 1k λ 2k λ 3k λ 4k λ 5k

α 21k λ 1k α 32k λ 2k α 43k λ 3k α 54k λ 4k

A B C D E

1 2 3 4 5

g

10k

α 42k λ 2k

g

20k

Acetone

{ } g 30k {Water} α 15k λ 5k

hydrogen

{ }

Isopropyl

alcohol

Figure 4.13. Split-fractions and fresh feeds

1 2 3 4 5

1 1 0 0 0 ˛ 15k 1k g 10k

2 ˛ 21k 1 0 0 0 2k g 20k

3 0 ˛ 32k 1 0 0

ð 3k D g 30k

4 0 ˛ 42k ˛ 43k 1 0 0

4k

5 0 0 0 ˛ 54k 1 0

5k

Figure 4.14. The set of equations

Estimation of the split-fraction coefficients

The values of the split-fraction coefficients will depend on the function of the processing

unit and the constraints on the stream flow-rates and compositions. Listed below are

suggested first trial values, and the basis for selecting the particular value for each

component.