Page 187 - Chemical process engineering design and economics

P. 187

Process Heat Transfer 169

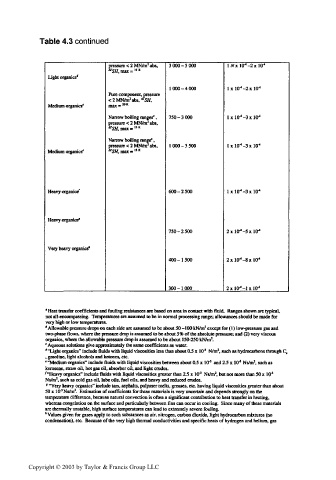

Table 4.3 continued

2

pressure < 2 MN/m abs, 3000-5000

**$//, max = ls K

Light organics'

4

1000-4000 Ixl0 -2xl<r >

Pure component, pressure

2

ir

<2MN/m abs, Sry,

Medium organics*

Narrow boiling ranges' . 750-3000 IxlO-'-SxlO"

2

pressure < 2 MN/m abs.

Narrow boiling range' ,

2

pressure < 2 MN/m abs. 1000-3500 Ixl0"-3xl0 4

Medium organics*

Heavy organics'' 600-2500 IxlfJ'-SxlO 4

Heavy organics*

750-2500 2x10^-5x10^

Very heavy organics*

400-1500 2x10-* -SxlO 4

300-1000 2x10^1x10*

' Heat transfer coefficients and fouling resistances are based on area in contact with fluid. Ranges shown are typical,

not all-encompassing. Temperatures are assumed to be in normal processing range; allowances should be made for

very high or low temperatures.

'Allowable pressure drops on each side are assumed to be about 50-100 kN/m except for (1) low-pressure gas and

:

two-phase flows, where the pressure drop is assumed to be about 5% of the absolute pressure; and (2) very viscous

organics, where the allowable pressure drop is assumed to be about 150-250 kN/m . 2

' Aqueous solutions give approximately the same coefficients as water.

2

'"Light organics" include fluids with liquid viscosities less than about 0_5 x 10 J N/m , such as hydrocarbons through C,

, gasoline, light alcohols and ketones, etc.

3

3

2

' "Medium organics" include fluids with liquid viscosities between about 0.5 x IO" and 2.5 x 10" Ns/m , such as

kerosene, straw oil, hot gas oil, absorber oil, and light crudes.

'"Heavy organics" include fluids with liquid viscosities greater than 2 .5 x 10"' Ns/m, but not more than 50 x 10 J

2

Ns/m, such as cold gas oil, lube oils, fuel oils, and heavy and reduced crudes.

2

* "Very heavy organics" include tars, asphalts, polymer melts, greases, etc. having liquid viscosities greater than about

3

50 x l(V Ns/m . 2 Estimation of coefficients for these materials is very uncertain and depends strongly on the

temperature difference, because natural convection is often a significant contribution to heal transfer in heating,

whereas congelation on the surface and particularly between fins can occur in cooling. Since many of these materials

are thermally unstable, high surface temperatures can lead to extremely severe fouling.

'Values given for gases apply to such substances as air, nitrogen, carbon dioxide, light hydrocarbon mixtures (no

condensation), etc. Because of the very high thermal conductivities and specific heals of hydrogen and helium, gas

Copyright © 2003 by Taylor & Francis Group LLC