Page 186 - Chemical process engineering design and economics

P. 186

168 Chapter 4

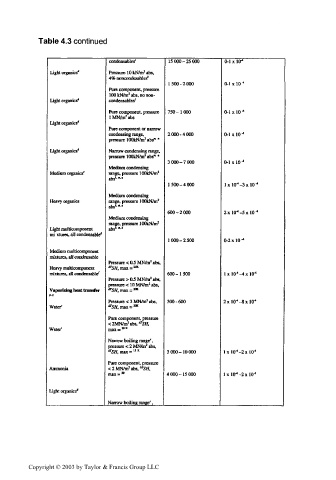

Table 4.3 continued

condensables' 15000-25000 0-1 xlO- 1

!

Light oiganics* Pressure 10 kN/m abs,

4% noncondesables*

1500-2000 0-1x10-"

Pure component, pressure

1

100 kN/ra abs, no non-

Light organics' condensables'

Pure component, pressure 750-1000 0-1x10'

1 MN/m' abs

Light organics'

Pure component or narrow

condensing range. 2000-4000 0-lxlO- 1

2

pressure 100kN/m abs* "

Light organics' Narrow condensing range,

pressure lOOkNAn' abs» •

3000-7000 0-lxlfl- 4

Medium condensing

Medium organics' range, pressure 100lcN/m 2

abs"-"" 4

1500-4000 ixicr'-Sxio-

Medium condensing

Heavy organics range, pressure lOOkN/m 2

abs'*"

600-2000 2x10-" -5x10"

Medium condensing

range, pressure 100kN/m 3

1

Light multicomponent abs *'

mi xtures, all condensable 4

1000-2500 0-2x10-*

Medium multicomponent

mixtures, all condensable

2

Pressure < 0 .5 MN/m abs,

:1J1

Heavy mullicomponent "•jff,max = '

mixtures, all condensable' 600-1500 lxlO- -4xlO J

1

2

Pressure > 0.5 MN/m abs,

1

pressure < 10 MN/m abs.

Vaporizing heat transfer "•S»,max = rai

At

1

Pressure < 3 MN/m abs, 300-600 2xlO- -8xlO- 1

2

Water" "Sftmax = OT

Pure component, pressure

2

<2MN/m abs,"SH,

Water 1 max = Blt

Narrow boiling range , 1

2

pressure < 2 MN/m abs,

1

1

ar 5ff,max= " 3000-10000 Ixl0- -2xl0 4

Pure component, pressure

ar

z

Ammonia <2MN/m abs, SH,

max= M 4000-15000 lx!0-'-2xlO- <

Light organics'

Narrow boiling range' ,

Copyright © 2003 by Taylor & Francis Group LLC