Page 185 - Chemical process engineering design and economics

P. 185

Process Heat Transfer 167

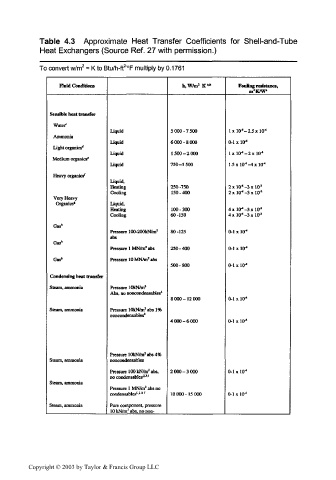

Table 4.3 Approximate Heat Transfer Coefficients for Shell-and-Tube

Heat Exchangers (Source Ref. 27 with permission.)

To convert w/m = K to Btu/h-ft^F multiply by 0.1761

2

1

l

Fluid Conditions h,WAn K * Fouling resistance,

m'K/W'

Sensible heat transfer

Water*

1

Liquid 5000-7500 IxlO" - 2.5x10''

Ammonia

Liquid 6000-8000 0-1 xlO 4

Light organics'

l

Liquid 1500-2000 Ixl0- -2xl0- 1

Medium organics*

Liquid 750-1500 UxlO-'-4xlO J

Heavy organics'

Liquid,

Heating 250-750 2x10^-3x10-'

Cooling 150-400 2xlO''-3xlO-*

Very Heavy

Organics' Liquid,

l

Heating 100-300 4xlO- -3xlO J

l

Cooling 60-150 4*10- -3xlO J

Gas"

Pressure lOO-MOkN/m 1 80 -125 0-1 x 10- 1

abs

Gas*

3

Pressure 1 MN/m abs 250-400 0-1 x Iff 4

Gas 1 Pressure 10 MN/m* abs

500-800 0-1 x 10 J

Condensing heat transfer

Steam, ammonia Pressure lOkN/m 2

Abs, no noncondensables'

8000-12000 0-1 xlO" 4

Steam, ammonia Pressure lOkN/m* abs 1%

noncondensables*

4000-6000 0-1x10^

Pressure lOkN/m* abs 4%

Steam, ammonia noncondensabks

1

Pressure 100 kN/m abs, 2000-3000 0-1 x 10 J

1

no condensables" *'

Steam, ammonia

2

Pressure 1 MN/m abs no

1

condensables'- " 10000-15000 0-1 xlO 4

Steam, ammonia Pure component, pressure

2

10 kN/m abs, no non-

Copyright © 2003 by Taylor & Francis Group LLC