Page 184 - Chemical process engineering design and economics

P. 184

166 Chapter 4

1

U 0= ———————————— (4.15)

Do 1 1

R fi + —— +— +Rf 0

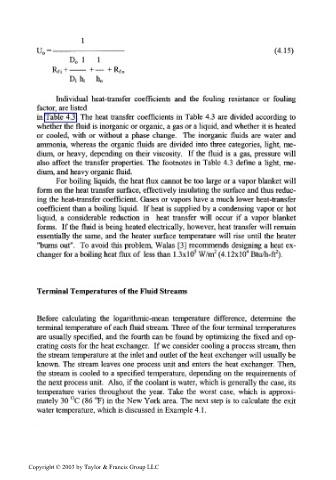

Individual heat-transfer coefficients and the fouling resistance or fouling

factor, are listed

in Table 4.3. The heat transfer coefficients in Table 4.3 are divided according to

whether the fluid is inorganic or organic, a gas or a liquid, and whether it is heated

or cooled, with or without a phase change. The inorganic fluids are water and

ammonia, whereas the organic fluids are divided into three categories, light, me-

dium, or heavy, depending on their viscosity. If the fluid is a gas, pressure will

also affect the transfer properties. The footnotes in Table 4.3 define a light, me-

dium, and heavy organic fluid.

For boiling liquids, the heat flux cannot be too large or a vapor blanket will

form on the heat transfer surface, effectively insulating the surface and thus reduc-

ing the heat-transfer coefficient. Gases or vapors have a much lower heat-transfer

coefficient than a boiling liquid. If heat is supplied by a condensing vapor or hot

liquid, a considerable reduction in heat transfer will occur if a vapor blanket

forms. If the fluid is being heated electrically, however, heat transfer will remain

essentially the same, and the heater surface temperature will rise until the heater

"burns out". To avoid this problem, Walas [3] recommends designing a heat ex-

changer for a boiling heat flux of less than 1.3xl05 W/m2 (4.12xl04 Btu/h-ft2).

Terminal Temperatures of the Fluid Streams

Before calculating the logarithmic-mean temperature difference, determine the

terminal temperature of each fluid stream. Three of the four terminal temperatures

are usually specified, and the fourth can be found by optimizing the fixed and op-

erating costs for the heat exchanger. If we consider cooling a process stream, then

the stream temperature at the inlet and outlet of the heat exchanger will usually be

known. The stream leaves one process unit and enters the heat exchanger. Then,

the stream is cooled to a specified temperature, depending on the requirements of

the next process unit. Also, if the coolant is water, which is generally the case, its

temperature varies throughout the year. Take the worst case, which is approxi-

mately 30 °C (86 °F) in the New York area. The next step is to calculate the exit

water temperature, which is discussed in Example 4.1.

Copyright © 2003 by Taylor & Francis Group LLC