Page 319 - Chemical process engineering design and economics

P. 319

298 Chapter 6

where the subscripts refer to heavy (H), light (L), and continuous phase (C).

The drop diameter, d, for use in Equation 6.16 is difficult to determine.

There is not a single drop size but a distribution of drop sizes. Jacobs and Penny

[17] recommend a drop diameter of 150 micrometers, which is conservative and

compensates somewhat for the other assumptions in Equation 6.16.

Once the drop terminal velocity is found, the time taken for the dispersed

phase to reach the interface is given by Equation 6.15.8 in Table 6.15, and the

decanter length required for the droplets to settle is given by Equation 6.15.9. The

maximum distance that the disperse phase droplets have to travel to reach the in-

terface, which is located at the center of the separator, is D/2. The distance varies

from zero to D/2. Also, the path of the droplets is not straight down or up but will

curve because of the motion of the phases.

The length of the coalescing zone of the decanter is determined by the time

required for the dispersed phase to coalesce. Coalescence could occur by drop to

drop coalescence and drop to interface coalescence. There is no relationship that

can predict the time required for coalescence, which according to Drown and

Thomson [18] could vary from seconds to many hours. Coalescence is enhanced

when the continuous phase viscosity is small, the density difference between

phases large, the interfacial tension large, and the temperature high. Because of the

time it takes for coalescence, the dispersed phase drops accumulate near the inter-

face to form a dispersion zone. Jacobs and Penny [17] recommend that the disper-

sion zone thickness be kept to less than or equal to 10% of the decanter diameter

as given by Equation 6.15.10. Also, the drops occupy about half of the volume of

the dispersion zone volume. Neglecting the curvature of the separator, the disper-

sion zone volume is equal to H A], where H is the thickness of the dispersion

D D

zone, and AI is the area of the interface. Therefore, the residence time, IR, of the

drops in the dispersion zone is given by Equation 6.15.11. The residence time is

specified by experience, and the interfacial area required for coalescence is calcu-

lated. If it is assumed that the interface will be located at the center of the de-

canter, then the length of the coalescing zone, L D, is calculated from Equation

6.15.12. The total length of the decanter is the sum of the lengths required for set-

tling and coalescence. The procedure for calculating the dimensions of a decanter

is given in Table 6.16, and Example 6.4 illustrates the procedure.

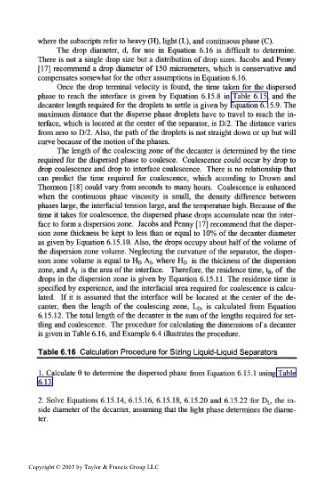

Table 6.16 Calculation Procedure for Sizing Liquid-Liquid Separators

1. Calculate 6 to determine the dispersed phase from Equation 6.15.1 using Table

6.13.

2. Solve Equations 6.15.14, 6.15.16, 6.15.18, 6.15.20 and 6.15.22 for D L, the in-

side diameter of the decanter, assuming that the light phase determines the diame-

ter.

Copyright © 2003 by Taylor & Francis Group LLC