Page 88 - Chemical process engineering design and economics

P. 88

Production and Capital Cost Estimation 73

L Flue Gas

Reactor

Air Cooler

Chloride

Propylene

Vfenturl Mbcer

T

Fuel Oil Chlorine

Steam O——* Mr

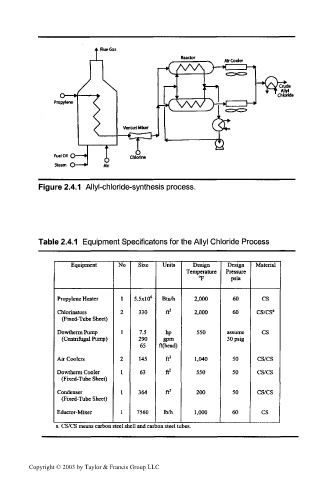

Figure 2.4.1 Allyl-chloride-synthesis process.

Table 2.4.1 Equipment Specificatons for the Allyl Chloride Process

Equipment No Size Units Design Design Material

Temperature Pressure

°F psia

Propylene Heater 1 5.5xl0 6 Btu/h 2,000 60 CS

Chlorinators 2 330 ft 2 2,000 60 CS/CS'

(Fixed-Tube Sheet)

Dowtherm Pump 1 7.5 hp 550 assume CS

(Centrifugal Pump) 290 gpm 30 psig

65 ft(head)

Air Coolers 2 145 ft 2 1,040 50 CS/CS

Dowtherm Cooler 1 63 ft 2 550 50 CS/CS

(Fixed-Tube Sheet)

Condenser 1 364 ft 2 200 50 CS/CS

(Fixed-Tube Sheet)

Eductor-Mixer 1 7560 Ib/h 1,000 60 CS

a. CS/CS means carbon steel shell and carbon steel tubes.

Copyright © 2003 by Taylor & Francis Group LLC