Page 452 - Civil Engineering Formulas

P. 452

378 CHAPTER THIRTEEN

Methane + Carbon dioxide

Fixed cover

Gas storage

Sludge Sludge

Mixer

inlets outlets

Sludge heater

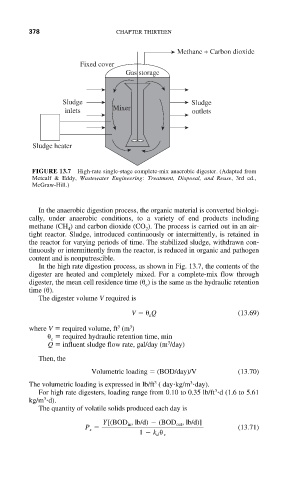

FIGURE 13.7 High-rate single-stage complete-mix anaerobic digester. (Adapted from

Metcalf & Eddy, Wastewater Engineering: Treatment, Disposal, and Reuse, 3rd ed.,

McGraw-Hill.)

In the anaerobic digestion process, the organic material is converted biologi-

cally, under anaerobic conditions, to a variety of end products including

methane (CH ) and carbon dioxide (CO ). The process is carried out in an air-

4

2

tight reactor. Sludge, introduced continuously or intermittently, is retained in

the reactor for varying periods of time. The stabilized sludge, withdrawn con-

tinuously or intermittently from the reactor, is reduced in organic and pathogen

content and is nonputrescible.

In the high rate digestion process, as shown in Fig. 13.7, the contents of the

digester are heated and completely mixed. For a complete-mix flow through

digester, the mean cell residence time ( ) is the same as the hydraulic retention

c

time ( ).

The digester volume V required is

V Q (13.69)

c

3

3

where V required volume, ft (m )

required hydraulic retention time, min

c

3

Q influent sludge flow rate, gal/day (m /day)

Then, the

Volumetric loading (BOD/day)/V (13.70)

The volumetric loading is expressed in lb/ft ( day kg/m day).

3

3

3

For high rate digesters, loading range from 0.10 to 0.35 lb/ft d (1.6 to 5.61

3

kg/m d).

The quantity of volatile solids produced each day is

Y[(BOD in , lb/d) (BOD out , lb/d)]

P x (13.71)

1 k d c