Page 326 - Compression Machinery for Oil and Gas

P. 326

312 SECTION II Types of Equipment

combustor has to be cooled, using air from the engine compressor. Additional

air from the engine compressor is mixed into the combustion products for fur-

ther cooling.

Unlike reciprocating engines, gas turbine combustion is continuous. This

has the advantage that the combustion process can be made very efficient, with

very low levels of products of incomplete combustion like carbon monoxide

(CO) or unburned hydrocarbons (UHCs). The other major emissions compo-

nent, oxides of nitrogen (NO x ), is not related to combustion efficiency, but

strictly to the temperature levels in the flame (and the amount of nitrogen in

the fuel). The solution to NO x emissions, therefore, lies in the lowering the

flame temperature. Initially, this was accomplished by injecting massive

amounts of steam or water in the flame zone, thus ‘cooling’ the flame. This

approach has significant drawbacks, not the least is the requirement to provide

large amounts (fuel-to-water ratios are approximately around 1) of extremely

clean water. Since the 1990s, combustion technology has focused on systems

often referred to as dry low NO x combustion, or lean-premix combustion

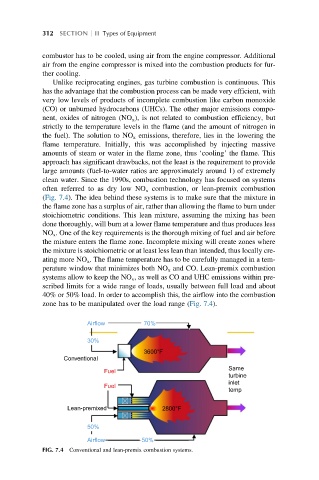

(Fig. 7.4). The idea behind these systems is to make sure that the mixture in

the flame zone has a surplus of air, rather than allowing the flame to burn under

stoichiometric conditions. This lean mixture, assuming the mixing has been

done thoroughly, will burn at a lower flame temperature and thus produces less

NO x . One of the key requirements is the thorough mixing of fuel and air before

the mixture enters the flame zone. Incomplete mixing will create zones where

the mixture is stoichiometric or at least less lean than intended, thus locally cre-

ating more NO x . The flame temperature has to be carefully managed in a tem-

perature window that minimizes both NO x and CO. Lean-premix combustion

systems allow to keep the NO x , as well as CO and UHC emissions within pre-

scribed limits for a wide range of loads, usually between full load and about

40% or 50% load. In order to accomplish this, the airflow into the combustion

zone has to be manipulated over the load range (Fig. 7.4).

Airflow 70%

30%

3600°F

Conventional

Same

Fuel

turbine

inlet

Fuel

temp

Lean-premixed 2800°F

50%

Airflow 50%

FIG. 7.4 Conventional and lean-premix combustion systems.