Page 333 - Compression Machinery for Oil and Gas

P. 333

318 SECTION II Types of Equipment

accumulated time during which the installation must be stopped to conduct rou-

tine maintenance. Gas engines require scheduled stoppages to inspect and/or

replace the spark plugs and to change the oil and filters. Other required adjust-

ments or component servicing can be performed less frequently, but still do fac-

tor into the overall owning and operating costs of the engine. Effective

operating strategies seek to extend these servicing intervals as much as possible

without risking component failures.

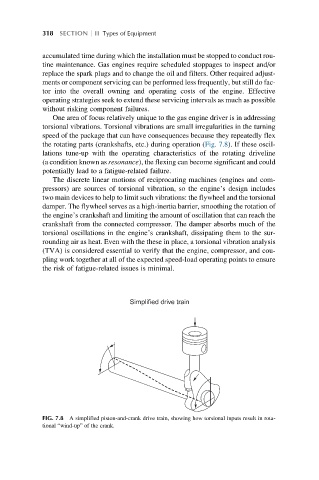

One area of focus relatively unique to the gas engine driver is in addressing

torsional vibrations. Torsional vibrations are small irregularities in the turning

speed of the package that can have consequences because they repeatedly flex

the rotating parts (crankshafts, etc.) during operation (Fig. 7.8). If these oscil-

lations tune-up with the operating characteristics of the rotating driveline

(a condition known as resonance), the flexing can become significant and could

potentially lead to a fatigue-related failure.

The discrete linear motions of reciprocating machines (engines and com-

pressors) are sources of torsional vibration, so the engine’s design includes

two main devices to help to limit such vibrations: the flywheel and the torsional

damper. The flywheel serves as a high-inertia barrier, smoothing the rotation of

the engine’s crankshaft and limiting the amount of oscillation that can reach the

crankshaft from the connected compressor. The damper absorbs much of the

torsional oscillations in the engine’s crankshaft, dissipating them to the sur-

rounding air as heat. Even with the these in place, a torsional vibration analysis

(TVA) is considered essential to verify that the engine, compressor, and cou-

pling work together at all of the expected speed-load operating points to ensure

the risk of fatigue-related issues is minimal.

Simplified drive train

FIG. 7.8 A simplified piston-and-crank drive train, showing how torsional inputs result in rota-

tional “wind-up” of the crank.