Page 211 - Corrosion Engineering Principles and Practice

P. 211

186 C h a p t e r 6 R e c o g n i z i n g t h e F o r m s o f C o r r o s i o n 187

(a)

(b)

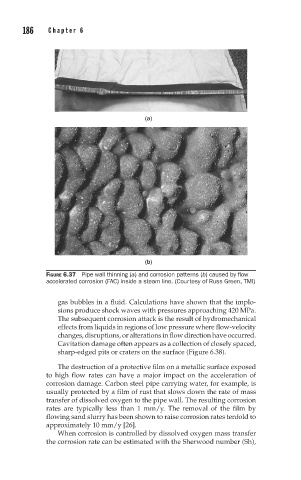

FIGURE 6.37 Pipe wall thinning (a) and corrosion patterns (b) caused by flow

accelerated corrosion (FAC) inside a steam line. (Courtesy of Russ Green, TMI)

gas bubbles in a fluid. Calculations have shown that the implo-

sions produce shock waves with pressures approaching 420 MPa.

The subsequent corrosion attack is the result of hydromechanical

effects from liquids in regions of low pressure where flow-velocity

changes, disruptions, or alterations in flow direction have occurred.

Cavitation damage often appears as a collection of closely spaced,

sharp-edged pits or craters on the surface (Figure 6.38).

The destruction of a protective film on a metallic surface exposed

to high flow rates can have a major impact on the acceleration of

corrosion damage. Carbon steel pipe carrying water, for example, is

usually protected by a film of rust that slows down the rate of mass

transfer of dissolved oxygen to the pipe wall. The resulting corrosion

rates are typically less than 1 mm/y. The removal of the film by

flowing sand slurry has been shown to raise corrosion rates tenfold to

approximately 10 mm/y [26].

When corrosion is controlled by dissolved oxygen mass transfer

the corrosion rate can be estimated with the Sherwood number (Sh),