Page 563 - Corrosion Engineering Principles and Practice

P. 563

526 C h a p t e r 1 3 C a t h o d i c P r o t e c t i o n 527

60

50

Cumulative corrosion leaks 30 CP restored

40

CP restored

CP interrupted

20

10 CP interrupted

CP first installed-1934

0

1930 1940 1950 1960 1970 1980 1990 2000

Year

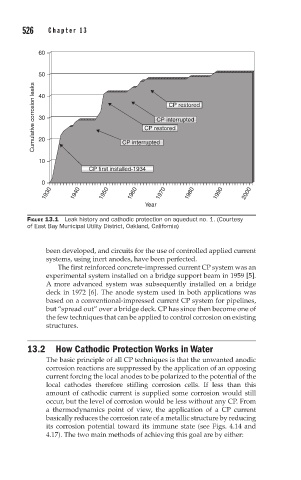

FIGURE 13.1 Leak history and cathodic protection on aqueduct no. 1. (Courtesy

of East Bay Municipal Utility District, Oakland, California)

been developed, and circuits for the use of controlled applied current

systems, using inert anodes, have been perfected.

The first reinforced concrete-impressed current CP system was an

experimental system installed on a bridge support beam in 1959 [5].

A more advanced system was subsequently installed on a bridge

deck in 1972 [6]. The anode system used in both applications was

based on a conventional-impressed current CP system for pipelines,

but “spread out” over a bridge deck. CP has since then become one of

the few techniques that can be applied to control corrosion on existing

structures.

13.2 How Cathodic Protection Works in Water

The basic principle of all CP techniques is that the unwanted anodic

corrosion reactions are suppressed by the application of an opposing

current forcing the local anodes to be polarized to the potential of the

local cathodes therefore stifling corrosion cells. If less than this

amount of cathodic current is supplied some corrosion would still

occur, but the level of corrosion would be less without any CP. From

a thermodynamics point of view, the application of a CP current

basically reduces the corrosion rate of a metallic structure by reducing

its corrosion potential toward its immune state (see Figs. 4.14 and

4.17). The two main methods of achieving this goal are by either: