Page 567 - Corrosion Engineering Principles and Practice

P. 567

530 C h a p t e r 1 3 C a t h o d i c P r o t e c t i o n 531

adjacent to the anodes, where the concentration of hydroxyl ions may

be very high. In addition, the high local currents around the anodes

may reduce the protection supplied to the rest of the structure.

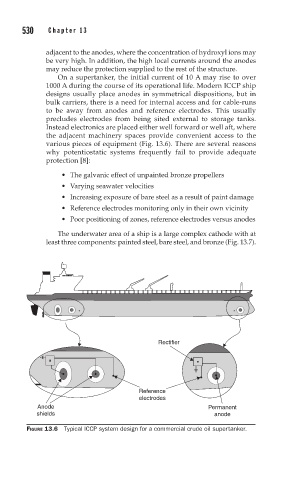

On a supertanker, the initial current of 10 A may rise to over

1000 A during the course of its operational life. Modern ICCP ship

designs usually place anodes in symmetrical dispositions, but in

bulk carriers, there is a need for internal access and for cable-runs

to be away from anodes and reference electrodes. This usually

precludes electrodes from being sited external to storage tanks.

Instead electronics are placed either well forward or well aft, where

the adjacent machinery spaces provide convenient access to the

various pieces of equipment (Fig. 13.6). There are several reasons

why potentiostatic systems frequently fail to provide adequate

protection [8]:

• The galvanic effect of unpainted bronze propellers

• Varying seawater velocities

• Increasing exposure of bare steel as a result of paint damage

• Reference electrodes monitoring only in their own vicinity

• Poor positioning of zones, reference electrodes versus anodes

The underwater area of a ship is a large complex cathode with at

least three components: painted steel, bare steel, and bronze (Fig. 13.7).

Rectifier

Reference

electrodes

Anode Permanent

shields anode

FIGURE 13.6 Typical ICCP system design for a commercial crude oil supertanker.