Page 231 - Defrosting for Air Source Heat Pump

P. 231

226 Defrosting for Air Source Heat Pump

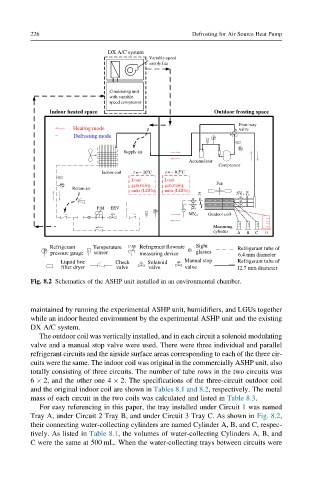

Fig. 8.2 Schematics of the ASHP unit installed in an environmental chamber.

maintained by running the experimental ASHP unit, humidifiers, and LGUs together

while an indoor heated environment by the experimental ASHP unit and the existing

DX A/C system.

The outdoor coil was vertically installed, and in each circuit a solenoid modulating

valve and a manual stop valve were used. There were three individual and parallel

refrigerant circuits and the airside surface areas corresponding to each of the three cir-

cuits were the same. The indoor coil was original in the commercially ASHP unit, also

totally consisting of three circuits. The number of tube rows in the two circuits was

6 2, and the other one 4 2. The specifications of the three-circuit outdoor coil

and the original indoor coil are shown in Tables 8.1 and 8.2, respectively. The metal

mass of each circuit in the two coils was calculated and listed in Table 8.3.

For easy referencing in this paper, the tray installed under Circuit 1 was named

Tray A, under Circuit 2 Tray B, and under Circuit 3 Tray C. As shown in Fig. 8.2,

their connecting water-collecting cylinders are named Cylinder A, B, and C, respec-

tively. As listed in Table 8.1, the volumes of water-collecting Cylinders A, B, and

C were the same at 500 mL. When the water-collecting trays between circuits were