Page 305 - Defrosting for Air Source Heat Pump

P. 305

Defrosting control strategy 299

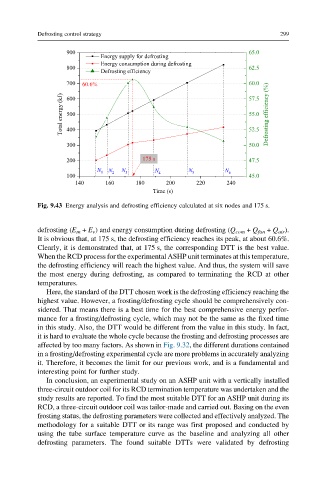

Fig. 9.43 Energy analysis and defrosting efficiency calculated at six nodes and 175 s.

defrosting (E m + E v ) and energy consumption during defrosting (Q com + Q fan + Q air ).

It is obvious that, at 175 s, the defrosting efficiency reaches its peak, at about 60.6%.

Clearly, it is demonstrated that, at 175 s, the corresponding DTT is the best value.

When the RCD process for the experimental ASHP unit terminates at this temperature,

the defrosting efficiency will reach the highest value. And thus, the system will save

the most energy during defrosting, as compared to terminating the RCD at other

temperatures.

Here, the standard of the DTT chosen work is the defrosting efficiency reaching the

highest value. However, a frosting/defrosting cycle should be comprehensively con-

sidered. That means there is a best time for the best comprehensive energy perfor-

mance for a frosting/defrosting cycle, which may not be the same as the fixed time

in this study. Also, the DTT would be different from the value in this study. In fact,

it is hard to evaluate the whole cycle because the frosting and defrosting processes are

affected by too many factors. As shown in Fig. 9.32, the different durations contained

in a frosting/defrosting experimental cycle are more problems in accurately analyzing

it. Therefore, it becomes the limit for our previous work, and is a fundamental and

interesting point for further study.

In conclusion, an experimental study on an ASHP unit with a vertically installed

three-circuit outdoor coil for its RCD termination temperature was undertaken and the

study results are reported. To find the most suitable DTT for an ASHP unit during its

RCD, a three-circuit outdoor coil was tailor-made and carried out. Basing on the even

frosting status, the defrosting parameters were collected and effectively analyzed. The

methodology for a suitable DTT or its range was first proposed and conducted by

using the tube surface temperature curve as the baseline and analyzing all other

defrosting parameters. The found suitable DTTs were validated by defrosting