Page 123 - Design and Operation of Heat Exchangers and their Networks

P. 123

Steady-state characteristics of heat exchangers 111

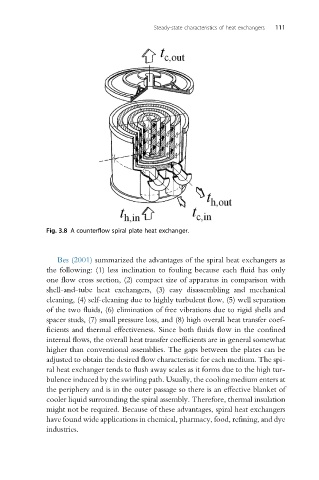

Fig. 3.8 A counterflow spiral plate heat exchanger.

Bes (2001) summarized the advantages of the spiral heat exchangers as

the following: (1) less inclination to fouling because each fluid has only

one flow cross section, (2) compact size of apparatus in comparison with

shell-and-tube heat exchangers, (3) easy disassembling and mechanical

cleaning, (4) self-cleaning due to highly turbulent flow, (5) well separation

of the two fluids, (6) elimination of free vibrations due to rigid shells and

spacer studs, (7) small pressure loss, and (8) high overall heat transfer coef-

ficients and thermal effectiveness. Since both fluids flow in the confined

internal flows, the overall heat transfer coefficients are in general somewhat

higher than conventional assemblies. The gaps between the plates can be

adjusted to obtain the desired flow characteristic for each medium. The spi-

ral heat exchanger tends to flush away scales as it forms due to the high tur-

bulence induced by the swirling path. Usually, the cooling medium enters at

the periphery and is in the outer passage so there is an effective blanket of

cooler liquid surrounding the spiral assembly. Therefore, thermal insulation

might not be required. Because of these advantages, spiral heat exchangers

have found wide applications in chemical, pharmacy, food, refining, and dye

industries.