Page 247 - Design for Six Sigma a Roadmap for Product Development

P. 247

Quality Function Deployment (QFD) 217

B E C

A

Customer

Customer Rest of

+ QFD Perceived

Needs DFSS

– Result

D

Customer

Satisfaction

Gauge

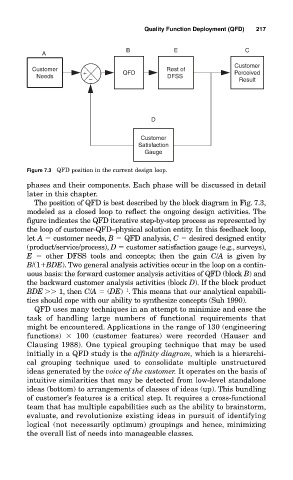

Figure 7.3 QFD position in the current design loop.

phases and their components. Each phase will be discussed in detail

later in this chapter.

The position of QFD is best described by the block diagram in Fig. 7.3,

modeled as a closed loop to reflect the ongoing design activities. The

figure indicates the QFD iterative step-by-step process as represented by

the loop of customer-QFD–physical solution entity. In this feedback loop,

let A customer needs, B QFD analysis, C desired designed entity

(product/service/process), D customer satisfaction gauge (e.g., surveys),

E other DFSS tools and concepts; then the gain C/A is given by

B/(1 BDE). Two general analysis activities occur in the loop on a contin-

uous basis: the forward customer analysis activities of QFD (block B) and

the backward customer analysis activities (block D). If the block product

1

BDE 1, then C/A (DE) . This means that our analytical capabili-

ties should cope with our ability to synthesize concepts (Suh 1990).

QFD uses many techniques in an attempt to minimize and ease the

task of handling large numbers of functional requirements that

might be encountered. Applications in the range of 130 (engineering

functions)

100 (customer features) were recorded (Hauser and

Clausing 1988). One typical grouping technique that may be used

initially in a QFD study is the affinity diagram, which is a hierarchi-

cal grouping technique used to consolidate multiple unstructured

ideas generated by the voice of the customer. It operates on the basis of

intuitive similarities that may be detected from low-level standalone

ideas (bottom) to arrangements of classes of ideas (up). This bundling

of customer’s features is a critical step. It requires a cross-functional

team that has multiple capabilities such as the ability to brainstorm,

evaluate, and revolutionize existing ideas in pursuit of identifying

logical (not necessarily optimum) groupings and hence, minimizing

the overall list of needs into manageable classes.