Page 249 - Design for Six Sigma a Roadmap for Product Development

P. 249

Quality Function Deployment (QFD) 219

7.4.1 Customer attributes (WHATs)

These are obtained from the voice of customer as represented by surveys,

claim data, warranty, and promotion campaigns. Usually customers use

fuzzy expressions in characterizing their needs with many dimensions

to be satisfied simultaneously. Affinity and tree diagrams may be used

to complete the list of needs. Most of these WHATs are very general

ideas that require more detailed definition. For example, customers

often say that they look for something “stylish” or “cool” when they

purchase a product. “Coolness” may be a very desirable feature, but

since it has different interpretations for different people, it cannot be

acted on directly. Legal and safety requirements or other internal wants

are considered extensions to the WHATs. The WHATs can be character-

ized using the Kano model (Sec. 7.5).

7.4.2 HOWs

The design features derived by the DFSS team to answer the WHATs

are called the HOWs. Each initial WHAT requires operational defini-

tions. The objective is to determine a set of critical-to-satisfaction

(CTS) requirements with which WHATs can be materialized. The

answering activity translates customer expectations into design crite-

ria such as speed, torque, and time to delivery. For each WHAT, there

should be one or more HOWs describing a means of attaining customer

satisfaction. For example, a “cool car” can be achieved through a “stylish”

body (different and new), seat design, legroom, lower noise, harshness,

and vibration requirements. At this stage only overall requirements

that can be measured and controlled need to be determined. These

substitute for the customer needs and expectations and are tradition-

ally known as substitute quality characteristics. In this book, we will

adopt the critical-to terminology aligning with Six Sigma.

Teams should define the HOWs in a solution-neutral environment

and not be restricted by listing specific parts and processes. Itemize

just the means (the HOWs), from which the list of WHATs can be

realized. The one-to-one relationships are not the real world, and

many HOWs will relate to many customer wants. In addition, each

HOW will have some direction of goodness or improvement of the

following:

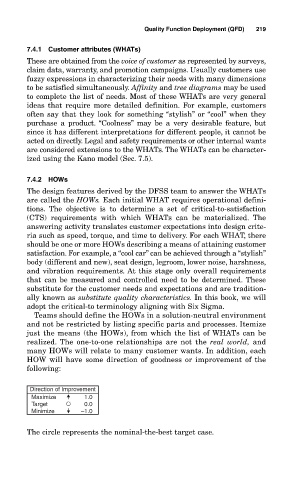

Direction of Improvement

Maximize 1.0

Target 0.0

Minimize –1.0

The circle represents the nominal-the-best target case.