Page 449 - Design for Six Sigma a Roadmap for Product Development

P. 449

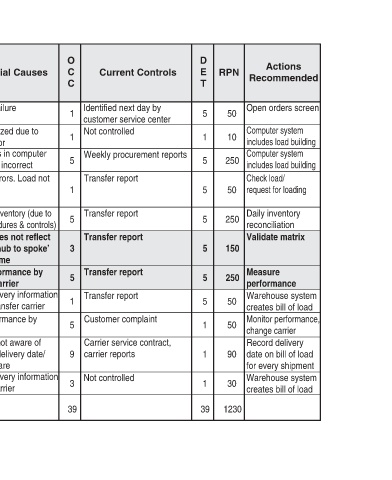

Actions Recommended Open orders screen Computer system includes load building Computer system includes load building Check load/ request for loading Daily inventory reconciliation Validate matrix Measure performance Warehouse system creates bill of load Monitor performance, change carr

RPN 50 10 250 50 250 150 250 50 50 90 30 1230

D E T 5 1 5 5 5 5 5 5 1 1 1 39

Current Controls Identified next day by customer service center Not controlled Weekly procurement reports Transfer report Transfer report Transfer report Transfer report Transfer report Customer complaint Carrier service contract, carrier reports Not controlled

O C C 1 1 5 1 5 3 5 1 5 9 3 39

Potential Causes Systems failure Not authorized due to clerical error Parameters in computer system are incorrect Loading errors. Load not Phantom inventory (due to poor procedures & controls) Matrix does not reflect realistic ‘hub to spoke’ transfer time Poor performance by transfer carr

S E V 10 10 10 checked 10 10 10 10 10 10 carrier 10 10 110

Potential Failure Effects Late delivery Late delivery Late delivery Late delivery Late delivery

Potential Failure Mode Warehouse shipping document does not print No transfer entered Hub warehouse does not load correctly onto transfer carrier Late delivery, spoke to customer Late delivery spoke to customer PFMEA of a distribution process.

Process Step/Input 1. Distribution 2. Distribution 3. Distribution 4. Distribution 5. Distribution Total Figure 11.7

409