Page 444 - Design for Six Sigma a Roadmap for Product Development

P. 444

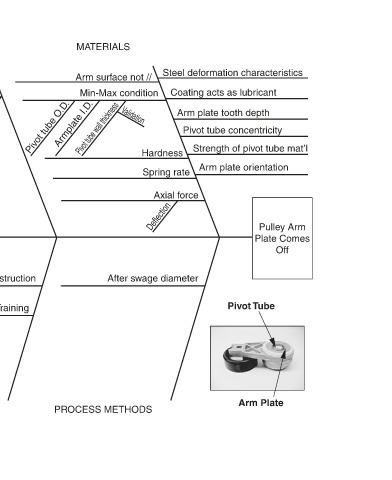

Steel deformation characteristics Coating acts as lubricant Arm plate tooth depth Pivot tube concentricity Strength of pivot tube mat’l Arm plate orientation Axial force Pulley Arm Plate Comes Off Pivot Tube Arm Plate

MATERIALS Arm surface not // Min-Max condition Pivot tube wall thickness Validation Hardness Spring rate Deflection After swage diameter PROCESS METHODS

Armplate I.D.

Pivot tube O.D.

Swage Wear of tool Operator Instruction Training

MACHINE Position Diameter Clamp Pressure PEOPLE

Groove No taper

Head Design Axial force Harmonic Validation Pulley armplate disassembly failure mode.

Deflection

ENVIRONMENT Loose mounting bolt Mishandling Internal vibration External vibration Axial load Against stop Improper belt No push-off test in place No push-off call-out on print MEASUREMENT

Installation load Figure 11.6

405