Page 64 - Design for Six Sigma a Roadmap for Product Development

P. 64

Six Sigma and Lean Fundamentals 41

Transportation Setup Inspection Staging

Staging

Casting Staging Machining Assembly

Time

Value-added time Nonvalue-added time

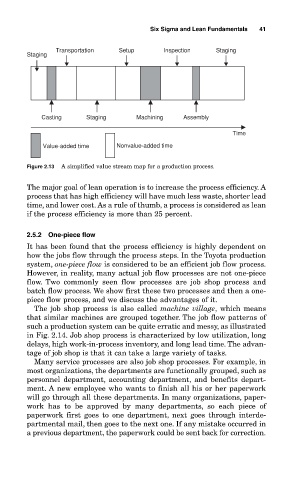

Figure 2.13 A simplified value stream map for a production process.

The major goal of lean operation is to increase the process efficiency. A

process that has high efficiency will have much less waste, shorter lead

time, and lower cost. As a rule of thumb, a process is considered as lean

if the process efficiency is more than 25 percent.

2.5.2 One-piece flow

It has been found that the process efficiency is highly dependent on

how the jobs flow through the process steps. In the Toyota production

system, one-piece flow is considered to be an efficient job flow process.

However, in reality, many actual job flow processes are not one-piece

flow. Two commonly seen flow processes are job shop process and

batch flow process. We show first these two processes and then a one-

piece flow process, and we discuss the advantages of it.

The job shop process is also called machine village, which means

that similar machines are grouped together. The job flow patterns of

such a production system can be quite erratic and messy, as illustrated

in Fig. 2.14. Job shop process is characterized by low utilization, long

delays, high work-in-process inventory, and long lead time. The advan-

tage of job shop is that it can take a large variety of tasks.

Many service processes are also job shop processes. For example, in

most organizations, the departments are functionally grouped, such as

personnel department, accounting department, and benefits depart-

ment. A new employee who wants to finish all his or her paperwork

will go through all these departments. In many organizations, paper-

work has to be approved by many departments, so each piece of

paperwork first goes to one department, next goes through interde-

partmental mail, then goes to the next one. If any mistake occurred in

a previous department, the paperwork could be sent back for correction.