Page 66 - Design for Six Sigma a Roadmap for Product Development

P. 66

Six Sigma and Lean Fundamentals 43

Raw Product

material

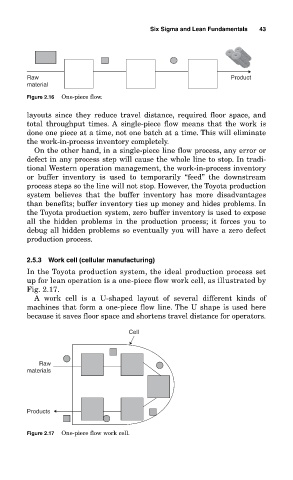

Figure 2.16 One-piece flow.

layouts since they reduce travel distance, required floor space, and

total throughput times. A single-piece flow means that the work is

done one piece at a time, not one batch at a time. This will eliminate

the work-in-process inventory completely.

On the other hand, in a single-piece line flow process, any error or

defect in any process step will cause the whole line to stop. In tradi-

tional Western operation management, the work-in-process inventory

or buffer inventory is used to temporarily “feed” the downstream

process steps so the line will not stop. However, the Toyota production

system believes that the buffer inventory has more disadvantages

than benefits; buffer inventory ties up money and hides problems. In

the Toyota production system, zero buffer inventory is used to expose

all the hidden problems in the production process; it forces you to

debug all hidden problems so eventually you will have a zero defect

production process.

2.5.3 Work cell (cellular manufacturing)

In the Toyota production system, the ideal production process set

up for lean operation is a one-piece flow work cell, as illustrated by

Fig. 2.17.

A work cell is a U-shaped layout of several different kinds of

machines that form a one-piece flow line. The U shape is used here

because it saves floor space and shortens travel distance for operators.

Cell

Raw

materials

Products

Figure 2.17 One-piece flow work cell.