Page 65 - Design for Six Sigma a Roadmap for Product Development

P. 65

42 Chapter Two

Figure 2.14 A typical flow pattern of a job shop.

Raw Product

material

Batches of semi-

finished products

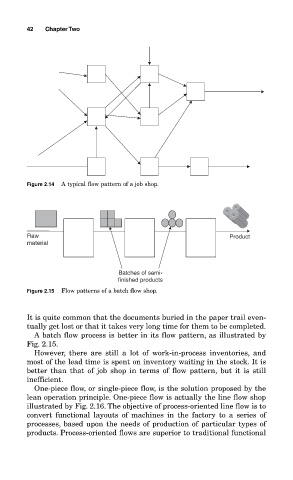

Figure 2.15 Flow patterns of a batch flow shop.

It is quite common that the documents buried in the paper trail even-

tually get lost or that it takes very long time for them to be completed.

A batch flow process is better in its flow pattern, as illustrated by

Fig. 2.15.

However, there are still a lot of work-in-process inventories, and

most of the lead time is spent on inventory waiting in the stock. It is

better than that of job shop in terms of flow pattern, but it is still

inefficient.

One-piece flow, or single-piece flow, is the solution proposed by the

lean operation principle. One-piece flow is actually the line flow shop

illustrated by Fig. 2.16. The objective of process-oriented line flow is to

convert functional layouts of machines in the factory to a series of

processes, based upon the needs of production of particular types of

products. Process-oriented flows are superior to traditional functional