Page 129 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 129

104 Chapter Six

Before QFD can be implemented, a multidisciplinary DFSS team needs to

be in place and more time should be spent upstream understanding customer

needs and expectations and defining the product or service in greater detail.

There are many initial realistic concerns that must be addressed in order to

implement QFD successfully. For example, departments represented in the

team do not tend to talk to one another. In addition, market research

information is not technically or design focused, and QFD is more easily

applied to incremental design than to brand creative design. The traditional

reality that problem prevention is not rewarded as well as problem solving

will be faced initially be the DFSS team. This “reality” will fade away as the

team embarks on its project using the rigor of DFSS.

6.4 QFD Methodology Overview

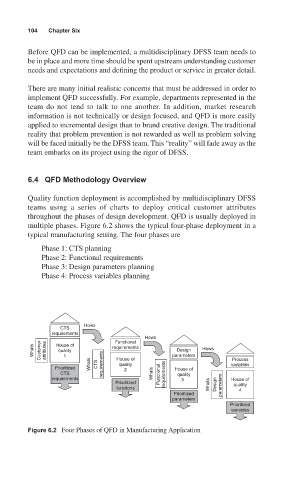

Quality function deployment is accomplished by multidisciplinary DFSS

teams using a series of charts to deploy critical customer attributes

throughout the phases of design development. QFD is usually deployed in

multiple phases. Figure 6.2 shows the typical four-phase deployment in a

typical manufacturing setting. The four phases are

Phase 1: CTS planning

Phase 2: Functional requirements

Phase 3: Design parameters planning

Phase 4: Process variables planning

Hows

CTS

requirements

Hows

Functional

Whats Customer attributes House of requirements parameters Hows

Design

quality

1

Process

Whats CTS requirements House of variables

quality

Prioritized 2 House of

CTS Whats Functional requirements quality

requirements 3 House of

Prioritized Whats Design quality

functions parameters 4

Prioritized

parameters

Prioritized

variables

Figure 6.2 Four Phases of QFD in Manufacturing Application