Page 275 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 275

244 Chapter Nine

The problem definition starts with several questions:

1. What is the problem?

2. What is the scope of the project?

3. What subsystem, system, and components are involved?

4. Do we have a current solution? Why is the current solution not good?

These are common questions to be asked in any engineering project. By

answering them, we are able to define the scope of the project and focus on

the right problem area.

Besides answering these common questions, several TRIZ methods are also

very helpful in the problem definition stage.

Functional Modeling and Functional Analysis

After identifying the project scope, it is very helpful to establish the

functional model of the subsystem involved in this project. Functional

modeling and analysis enables us to see the problem more clearly and

precisely. We recall the toothbrush example (Example 9.1) to illustrate how

functional analysis can help in the problem definition.

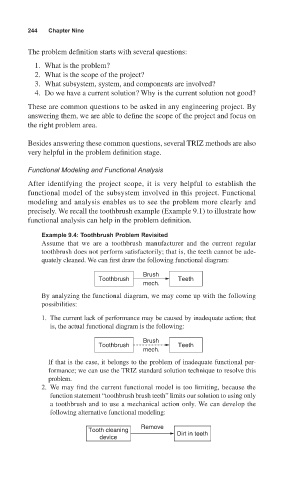

Example 9.4: Toothbrush Problem Revisited

Assume that we are a toothbrush manufacturer and the current regular

toothbrush does not perform satisfactorily; that is, the teeth cannot be ade-

quately cleaned. We can first draw the following functional diagram:

Brush

Toothbrush Teeth

mech.

By analyzing the functional diagram, we may come up with the following

possibilities:

1. The current lack of performance may be caused by inadequate action; that

is, the actual functional diagram is the following:

Brush

Toothbrush Teeth

mech.

If that is the case, it belongs to the problem of inadequate functional per-

formance; we can use the TRIZ standard solution technique to resolve this

problem.

2. We may find the current functional model is too limiting, because the

function statement “toothbrush brush teeth” limits our solution to using only

a toothbrush and to use a mechanical action only. We can develop the

following alternative functional modeling:

Remove

Tooth cleaning Dirt in teeth

device