Page 415 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 415

374 Chapter Ten

the inventory person in the supermarket will refill the same amount of items

by pulling them from the warehouse; then the warehouse person will order

roughly the same amount of items that were pulled from the warehouse.

Restaurant operation is a perfect example of pull-based production. The

customer places the order, and then the kitchen produces exactly what the

customer ordered. In general, the key feature for pull-based production is

that the information flow direction is opposite to that of the material flow.

The information flow means the production control order. In the restaurant

case, the production control is the order for the kitchen to cook. This order’s

direction is from customer to kitchen; on the other hand, the direction of

material flow is the flow of food in the restaurant case, the direction from the

kitchen to the customer. Clearly, the information flow direction and material

flow direction in the restaurant kitchen are opposite to each other.

The opposite of pull-based production is push-based production. The key

feature for the push-based production is that the direction of information

flow is the same as that of the material flow. In push-based production, each

work stop sends the work downstream of the operation, that is, pushes the

work downstream, without considering whether the downstream areas can

make use of it. Typically, activities are planned centrally but do not reflect

actual conditions in terms of idle time, inventory, and queues.

Agricultural production is a typical push-based production. Because the

production cycle is very long, there is no way that farmers can produce only

the amount of food based on real-time demand. The production plan is

purely based on market forecasts and sometimes just based on last year’s

production. The production command will flow in the same direction as the

work flow. It is well known that agricultural production often suffers from

oversupply and market fluctuations. Clearly, pull-based production,

whenever possible, will create much less overproduction, so the waste

caused by overproduction can be reduced.

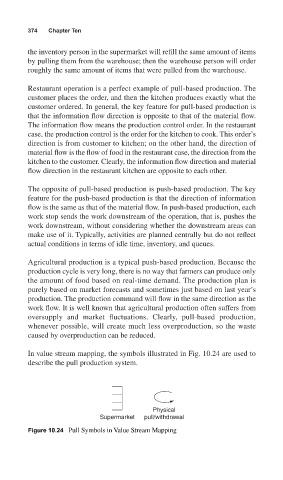

In value stream mapping, the symbols illustrated in Fig. 10.24 are used to

describe the pull production system.

Physical

Supermarket pull/withdrawal

Figure 10.24 Pull Symbols in Value Stream Mapping