Page 412 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 412

Design and Improvement of Service Processes—Process Management 371

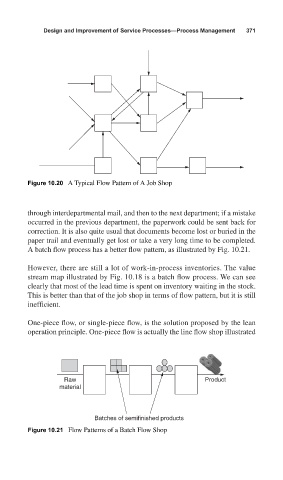

Figure 10.20 A Typical Flow Pattern of A Job Shop

through interdepartmental mail, and then to the next department; if a mistake

occurred in the previous department, the paperwork could be sent back for

correction. It is also quite usual that documents become lost or buried in the

paper trail and eventually get lost or take a very long time to be completed.

A batch flow process has a better flow pattern, as illustrated by Fig. 10.21.

However, there are still a lot of work-in-process inventories. The value

stream map illustrated by Fig. 10.18 is a batch flow process. We can see

clearly that most of the lead time is spent on inventory waiting in the stock.

This is better than that of the job shop in terms of flow pattern, but it is still

inefficient.

One-piece flow, or single-piece flow, is the solution proposed by the lean

operation principle. One-piece flow is actually the line flow shop illustrated

Raw Product

material

Batches of semifinished products

Figure 10.21 Flow Patterns of a Batch Flow Shop