Page 409 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 409

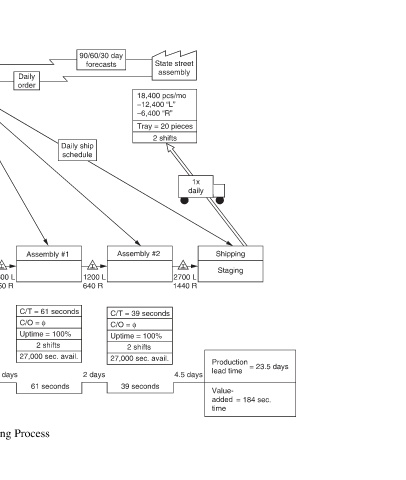

Production = 23.5 days = 184 sec.

Shipping Staging lead time Value- added time

1x daily 4.5 days

State street assembly 18,400 pcs/mo −12,400 “L” −6,400 “R” Tray = 20 pieces 2 shifts Assembly #2 2700 L 1440 R C/T = 39 seconds 27,000 sec. avail. 39 seconds

90/60/30 day forecasts 1200 L 640 R C/O = φ Uptime = 100% 2 shifts 2 days

Daily ship schedule

Assembly #1 C/T = 61 seconds Uptime = 100% 2 shifts 27,000 sec. avail. 61 seconds

Daily order C/O = φ

1600 L 850 R 2.6 days

Production control MRP Weekly schedule S. weld #2 C/T = 45 seconds C/O = 10 minutes Uptime = 80% 2 shifts 27,000 sec. avail. 45 seconds

6-week forecast 1100 L 600 R 1.8 days A Complete Value Stream Map for a Manufacturing Process

Weekly fax S. weld #1 C/T = 38 seconds C/O = 10 minutes Uptime = 100% 2 shifts 27,000 sec. avail. 38 seconds

Michigan Steel Co. 500-ft coils 4600 L 2400 R 7.6 days

Tues. + Thurs.

Stamping 200 T C/T = 1 second C/O = 1 hour Uptime = 85% 27,000 sec. avail. EPE = 2 weeks 1 second

Coils 5 days 5 days Figure 10.18

368