Page 123 - Design of Simple and Robust Process Plants

P. 123

108 Chapter 4 Process Synthesis and Design Optimization

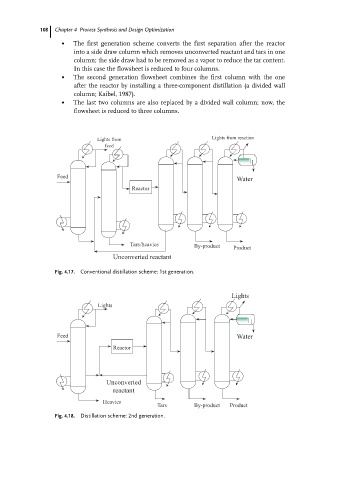

. The first generation scheme converts the first separation after the reactor

into a side draw column which removes unconverted reactant and tars in one

column; the side draw had to be removed as a vapor to reduce the tar content.

In this case the flowsheet is reduced to four columns.

. The second generation flowsheet combines the first column with the one

after the reactor by installing a three-component distillation (a divided wall

column; Kaibel, 1987).

. The last two columns are also replaced by a divided wall column; now, the

flowsheet is reduced to three columns.

Lights from reaction

Lights from

feed

Feed

Water

Reactor

Tars/heavies By-product Product

Unconverted reactant

Fig. 4.17. Conventional distillation scheme: 1st generation.

Lights

Lights

Feed Water

Reactor

Unconverted

reactant

Heavies

Tars By-product Product

Fig. 4.18. Distillation scheme: 2nd generation.