Page 243 - Design of Solar Thermal Power Plants

P. 243

226 4. DESIGN OF THE CONCENTRATION SYSTEM

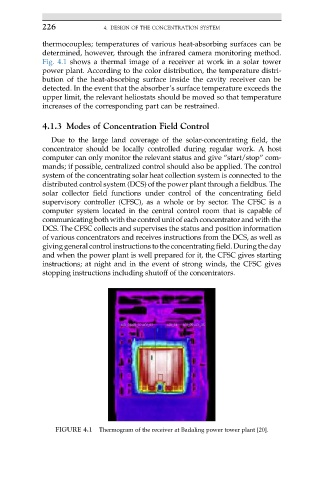

thermocouples; temperatures of various heat-absorbing surfaces can be

determined, however, through the infrared camera monitoring method.

Fig. 4.1 shows a thermal image of a receiver at work in a solar tower

power plant. According to the color distribution, the temperature distri-

bution of the heat-absorbing surface inside the cavity receiver can be

detected. In the event that the absorber’s surface temperature exceeds the

upper limit, the relevant heliostats should be moved so that temperature

increases of the corresponding part can be restrained.

4.1.3 Modes of Concentration Field Control

Due to the large land coverage of the solar-concentrating field, the

concentrator should be locally controlled during regular work. A host

computer can only monitor the relevant status and give “start/stop” com-

mands; if possible, centralized control should also be applied. The control

system of the concentrating solar heat collection system is connected to the

distributed control system (DCS) of the power plant through a fieldbus. The

solar collector field functions under control of the concentrating field

supervisory controller (CFSC), as a whole or by sector. The CFSC is a

computer system located in the central control room that is capable of

communicating both with the control unit of each concentrator and with the

DCS. The CFSC collects and supervises the status and position information

of various concentrators and receives instructions from the DCS, as well as

giving general control instructions tothe concentrating field. During the day

and when the power plant is well prepared for it, the CFSC gives starting

instructions; at night and in the event of strong winds, the CFSC gives

stopping instructions including shutoff of the concentrators.

FIGURE 4.1 Thermogram of the receiver at Badaling power tower plant [20].