Page 306 - Distributed model predictive control for plant-wide systems

P. 306

280 Distributed Model Predictive Control for Plant-Wide Systems

Cooling load Cooling load Cooling load Cooling load

(High floors) (Middle floors) (Middle floors) (Lower floors)

Water cooling network

Large power Small power

Conventional Exchanger Conventional

refrigerator V3 refrigeratior

V2

V4

Ice storage tank

Dual Mode V1

Chiller

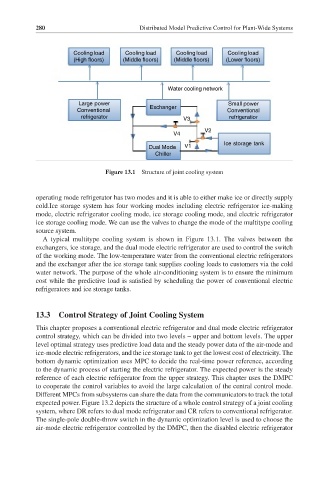

Figure 13.1 Structure of joint cooling system

operating mode refrigerator has two modes and it is able to either make ice or directly supply

cold.Ice storage system has four working modes including electric refrigerator ice-making

mode, electric refrigerator cooling mode, ice storage cooling mode, and electric refrigerator

ice storage cooling mode. We can use the valves to change the mode of the multitype cooling

source system.

A typical multitype cooling system is shown in Figure 13.1. The valves between the

exchangers, ice storage, and the dual mode electric refrigerator are used to control the switch

of the working mode. The low-temperature water from the conventional electric refrigerators

and the exchanger after the ice storage tank supplies cooling loads to customers via the cold

water network. The purpose of the whole air-conditioning system is to ensure the minimum

cost while the predictive load is satisfied by scheduling the power of conventional electric

refrigerators and ice storage tanks.

13.3 Control Strategy of Joint Cooling System

This chapter proposes a conventional electric refrigerator and dual mode electric refrigerator

control strategy, which can be divided into two levels – upper and bottom levels. The upper

level optimal strategy uses predictive load data and the steady power data of the air-mode and

ice-mode electric refrigerators, and the ice storage tank to get the lowest cost of electricity. The

bottom dynamic optimization uses MPC to decide the real-time power reference, according

to the dynamic process of starting the electric refrigerator. The expected power is the steady

reference of each electric refrigerator from the upper strategy. This chapter uses the DMPC

to cooperate the control variables to avoid the large calculation of the central control mode.

Different MPCs from subsystems can share the data from the communicators to track the total

expected power. Figure 13.2 depicts the structure of a whole control strategy of a joint cooling

system, where DR refers to dual mode refrigerator and CR refers to conventional refrigerator.

The single-pole double-throw switch in the dynamic optimization level is used to choose the

air-mode electric refrigerator controlled by the DMPC, then the disabled electric refrigerator