Page 69 - Distributed model predictive control for plant-wide systems

P. 69

Control Structure of Distributed MPC 43

MPC

Communication

network

MPC MPC MPC MPC MPC

*

* y

u 1 * y 1 u 2 2 u 3 * y 3 u * m–1 y m–1 u y m

m

S *

S Na

S 1 S 2 S *

Plant-wide system S 3 S Na-1

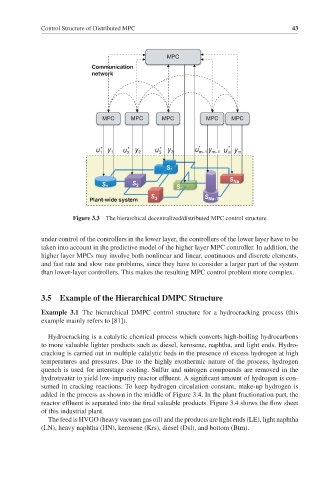

Figure 3.3 The hierarchical decentralized/distributed MPC control structure

under control of the controllers in the lower layer, the controllers of the lower layer have to be

taken into account in the predictive model of the higher layer MPC controller. In addition, the

higher layer MPCs may involve both nonlinear and linear, continuous and discrete elements,

and fast rate and slow rate problems, since they have to consider a larger part of the system

than lower-layer controllers. This makes the resulting MPC control problem more complex.

3.5 Example of the Hierarchical DMPC Structure

Example 3.1 The hierarchical DMPC control structure for a hydrocracking process (this

example mainly refers to [81]).

Hydrocracking is a catalytic chemical process which converts high-boiling hydrocarbons

to more valuable lighter products such as diesel, kerosene, naphtha, and light ends. Hydro-

cracking is carried out in multiple catalytic beds in the presence of excess hydrogen at high

temperatures and pressures. Due to the highly exothermic nature of the process, hydrogen

quench is used for interstage cooling. Sulfur and nitrogen compounds are removed in the

hydrotreater to yield low-impurity reactor effluent. A significant amount of hydrogen is con-

sumed in cracking reactions. To keep hydrogen circulation constant, make-up hydrogen is

added in the process as shown in the middle of Figure 3.4. In the plant fractionation part, the

reactor effluent is separated into the final valuable products. Figure 3.4 shows the flow sheet

of this industrial plant.

The feed is HVGO (heavy vacuum gas oil) and the products are light ends (LE), light naphtha

(LN), heavy naphtha (HN), kerosene (Krs), diesel (Dsl), and bottom (Btm).