Page 263 - Electric Drives and Electromechanical Systems

P. 263

260 Electric Drives and Electromechanical Systems

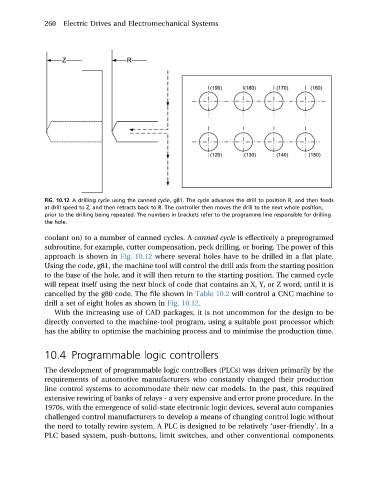

FIG. 10.12 A drilling cycle using the canned cycle, g81. The cycle advances the drill to position R, and then feeds

at drill speed to Z, and then retracts back to R. The controller then moves the drill to the next whole position,

prior to the drilling being repeated. The numbers in brackets refer to the programme line responsible for drilling

the hole.

coolant on) to a number of canned cycles. A canned cycle is effectively a preprogramed

subroutine, for example, cutter compensation, peck drilling, or boring. The power of this

approach is shown in Fig. 10.12 where several holes have to be drilled in a flat plate.

Using the code, g81, the machine tool will control the drill axis from the starting position

to the base of the hole, and it will then return to the starting position. The canned cycle

will repeat itself using the next block of code that contains an X, Y, or Z word, until it is

cancelled by the g80 code. The file shown in Table 10.2 will control a CNC machine to

drill a set of eight holes as shown in Fig. 10.12.

With the increasing use of CAD packages, it is not uncommon for the design to be

directly converted to the machine-tool program, using a suitable post processor which

has the ability to optimise the machining process and to minimise the production time.

10.4 Programmable logic controllers

The development of programmable logic controllers (PLCs) was driven primarily by the

requirements of automotive manufacturers who constantly changed their production

line control systems to accommodate their new car models. In the past, this required

extensive rewiring of banks of relays - a very expensive and error prone procedure. In the

1970s, with the emergence of solid-state electronic logic devices, several auto companies

challenged control manufacturers to develop a means of changing control logic without

the need to totally rewire system. A PLC is designed to be relatively ‘user-friendly’. In a

PLC based system, push-buttons, limit switches, and other conventional components