Page 77 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 77

TRANSFORMER COMPONENTS AND MAINTENANCE

4.6 CHAPTER FOUR

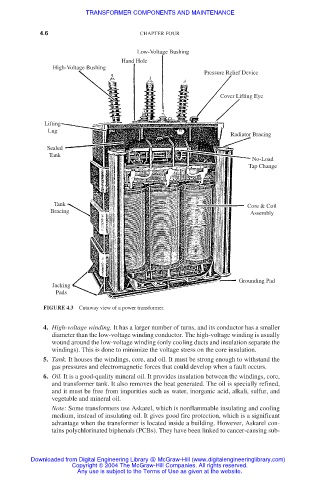

Low-Voltage Bushing

Hand Hole

High-Voltage Bushing

Pressure Relief Device

Cover Lifting Eye

Lifting

Lug

Radiator Bracing

Sealed

Tank

No-Load

Tap Change

Tank Core & Coil

Bracing Assembly

Grounding Pad

Jacking

Pads

FIGURE 4.3 Cutaway view of a power transformer.

4. High-voltage winding. It has a larger number of turns, and its conductor has a smaller

diameter than the low-voltage winding conductor. The high-voltage winding is usually

wound around the low-voltage winding (only cooling ducts and insulation separate the

windings). This is done to minimize the voltage stress on the core insulation.

5. Tank. It houses the windings, core, and oil. It must be strong enough to withstand the

gas pressures and electromagnetic forces that could develop when a fault occurs.

6. Oil. It is a good-quality mineral oil. It provides insulation between the windings, core,

and transformer tank. It also removes the heat generated. The oil is specially refined,

and it must be free from impurities such as water, inorganic acid, alkali, sulfur, and

vegetable and mineral oil.

Note: Some transformers use Askarel, which is nonflammable insulating and cooling

medium, instead of insulating oil. It gives good fire protection, which is a significant

advantage when the transformer is located inside a building. However, Askarel con-

tains polychlorinated biphenals (PCBs). They have been linked to cancer-causing sub-

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.