Page 74 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 74

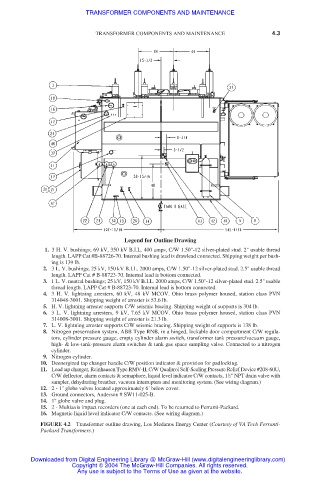

TRANSFORMER COMPONENTS AND MAINTENANCE

TRANSFORMER COMPONENTS AND MAINTENANCE 4.3

Legend for Outline Drawing

1. 3 H. V. bushings; 69 kV, 350 kV B.I.L. 400 amps, C/W 1.50"-12 silver-plated stud. 2" usable thread

length. LAPP Cat #B-88726-70. Internal bushing lead is drawlead connected. Shipping weight per bush-

ing is 139 lb.

2. 3 L. V. bushings; 25 kV, 150 kV B.I.L. 2000 amps, C/W 1.50"-12 silver-plated stud. 2.5" usable thread

length. LAPP Cat # B-88723-70. Internal lead is bottom connected.

3. 1 L. V. neutral bushings; 25 kV, 150 kV B.I.L. 2000 amps, C/W 1.50"-12 silver-plated stud. 2.5" usable

thread length. LAPP Cat # B-88723-70. Internal lead is bottom connected.

4. 3 H. V. lightning arresters, 60 kV, 48 kV MCOV. Ohio brass polymer housed, station class PVN

314048-3001. Shipping weight of arrester is 53.6 lb.

5. H. V. lightning arrester supports C/W seismic bracing. Shipping weight of supports is 304 lb.

6. 3 L. V. lightning arresters, 9 kV, 7.65 kV MCOV. Ohio brass polymer housed, station class PVN

314008-3001. Shipping weight of arrester is 21.3 lb.

7. L. V. lightning arrester supports C/W seismic bracing. Shipping weight of supports is 138 lb.

8. Nitrogen preservation system, ABB Type RNB, in a hinged, lockable door compartment C/W regula-

tors, cylinder pressure gauge, empty cylinder alarm switch, transformer tank pressure/vacuum gauge,

high- & low-tank-pressure alarm switches & tank gas space sampling valve. Connected to a nitrogen

cylinder.

9. Nitrogen cylinder.

10. Deenergized tap changer handle C/W position indicator & provision for padlocking.

11. Load tap changer, Reinhausen Type RMV-II, C/W Qualitrol Self-Sealing Pressure Relief Device #208-60U,

C/W deflector, alarm contacts & semaphore, liquid level indicator C/W contacts, 1 ⁄2" NPT drain valve with

1

sampler, dehydrating breather, vacuum interrupters and monitoring system. (See wiring diagram.)

12. 2 - 1" globe valves located approximately 6' below cover.

13. Ground connectors, Anderson # SW11-025-B.

14. 1" globe valve and plug.

15. 2 - Multiaxis impact recorders (one at each end). To be returned to Ferranti-Packard.

16. Magnetic liquid level indicator C/W contacts. (See wiring diagram.)

FIGURE 4.2 Transformer outline drawing, Los Medanos Energy Center (Courtesy of VA Tech Ferranti-

Packard Transformers.)

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.