Page 167 - Electromechanical Devices and Components Illustrated Sourcebook

P. 167

Chapter 7 Heating 129

Coil

Terminal

Component to

be Heated Eddy Currents

Terminal

RF Power Supply

Figure 7-6 Induction Heating Schematic

Open Element for

Model Airplane Engines

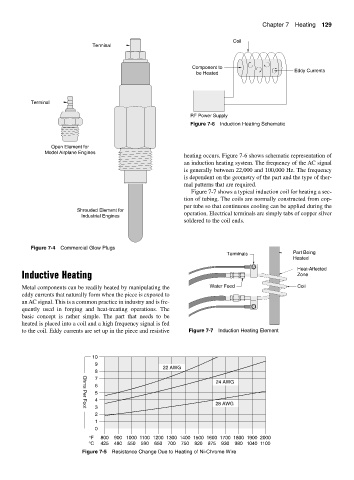

heating occurs. Figure 7-6 shows schematic representation of

an induction heating system. The frequency of the AC signal

is generally between 22,000 and 100,000 Hz. The frequency

is dependent on the geometry of the part and the type of ther-

mal patterns that are required.

Figure 7-7 shows a typical induction coil for heating a sec-

tion of tubing. The coils are normally constructed from cop-

per tube so that continuous cooling can be applied during the

Shrouded Element for

Industrial Engines operation. Electrical terminals are simply tabs of copper silver

soldered to the coil ends.

Figure 7-4 Commercial Glow Plugs

Terminals Part Being

Heated

Heat-Affected

Inductive Heating Zone

Metal components can be readily heated by manipulating the Water Feed Coil

eddy currents that naturally form when the piece is exposed to

an AC signal. This is a common practice in industry and is fre-

quently used in forging and heat-treating operations. The

basic concept is rather simple. The part that needs to be

heated is placed into a coil and a high frequency signal is fed

to the coil. Eddy currents are set up in the piece and resistive Figure 7-7 Induction Heating Element

10

9

22 AWG

8

7

24 AWG

6

5

4

28 AWG

3

Ohms Per Foot

2

1

0

°F 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

°C 425 480 550 590 650 700 750 820 875 930 980 1040 1100

Figure 7-5 Resistance Change Due to Heating of Ni-Chrome Wire