Page 168 - Electromechanical Devices and Components Illustrated Sourcebook

P. 168

130 Electromechanical Devices & Components Illustrated Sourcebook

Resistive Heating Drive Motors

Arc Carbon

Resistively heating a part is using the part itself as the heating Electrodes

element. Generally, the component to be heated is connected + −

to a high-current power supply, as shown in Figure 7-8. When

the power supply is turned on, the component will be heated Pinch Rollers

between the two terminals.

The most common use for resistive heating is to thaw

frozen water pipes, as shown in Figure 7-9. In this case, a

small AC arc welder is connected to either end of the exposed

Feed

pipe and then switched on. The pipe slowly warms, and the Controller

internal ice melts. AC Ignition Supply

Current Transformer

+ −

DC Power Supply

Heat-Affected Zone Figure 7-10 Carbon Arc Schematic

Component to

be Heated

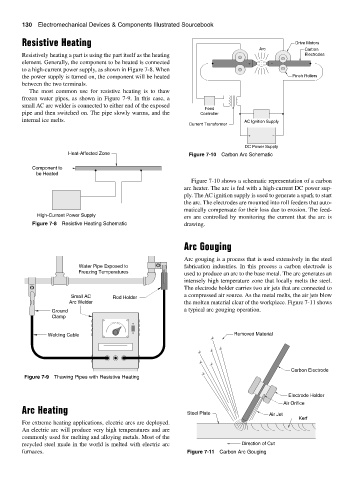

Figure 7-10 shows a schematic representation of a carbon

arc heater. The arc is fed with a high-current DC power sup-

ply. The AC ignition supply is used to generate a spark to start

the arc. The electrodes are mounted into roll feeders that auto-

matically compensate for their loss due to erosion. The feed-

High-Current Power Supply ers are controlled by monitoring the current that the arc is

Figure 7-8 Resistive Heating Schematic drawing.

Arc Gouging

Arc gouging is a process that is used extensively in the steel

Water Pipe Exposed to fabrication industries. In this process a carbon electrode is

Freezing Temperatures used to produce an arc to the base metal. The arc generates an

intensely high temperature zone that locally melts the steel.

The electrode holder carries two air jets that are connected to

Small AC Rod Holder a compressed air source. As the metal melts, the air jets blow

Arc Welder the molten material clear of the workpiece. Figure 7-11 shows

Ground a typical arc gouging operation.

Clamp

Welding Cable Removed Material

Carbon Electrode

Figure 7-9 Thawing Pipes with Resistive Heating

Electrode Holder

Air Orifice

Arc Heating Steel Plate

Air Jet

Kerf

For extreme heating applications, electric arcs are deployed.

An electric arc will produce very high temperatures and are

commonly used for melting and alloying metals. Most of the

recycled steel made in the world is melted with electric arc Direction of Cut

furnaces. Figure 7-11 Carbon Arc Gouging