Page 169 - Electromechanical Devices and Components Illustrated Sourcebook

P. 169

Chapter 7 Heating 131

Arc Welding a separate rod. This process is very precise and is applicable

to almost any type of metal.

Probably the most common use for arc heating is electric

welding. This is a very common process that is used in all

types of manufactured products. There are many different Metal Inert Gas (MIG)

types of electric arc welding processes; however, there are

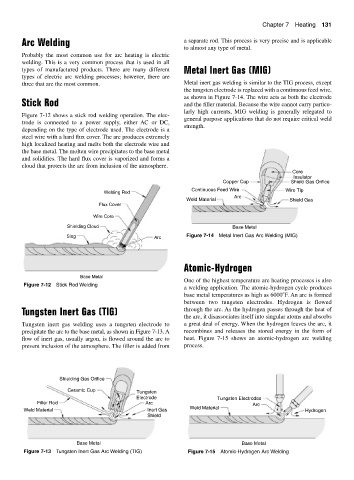

three that are the most common. Metal inert gas welding is similar to the TIG process, except

the tungsten electrode is replaced with a continuous feed wire,

as shown in Figure 7-14. The wire acts as both the electrode

Stick Rod and the filler material. Because the wire cannot carry particu-

larly high currents, MIG welding is generally relegated to

Figure 7-12 shows a stick rod welding operation. The elec-

general purpose applications that do not require critical weld

trode is connected to a power supply, either AC or DC,

strength.

depending on the type of electrode used. The electrode is a

steel wire with a hard flux cover. The arc produces extremely

high localized heating and melts both the electrode wire and

the base metal. The molten wire precipitates to the base metal

and solidifies. The hard flux cover is vaporized and forms a

cloud that protects the arc from inclusion of the atmosphere.

Core

Insulator

Copper Cup Shield Gas Orifice

Continuous Feed Wire Wire Tip

Welding Rod

Arc

Weld Material Shield Gas

Flux Cover

Wire Core

Shielding Cloud Base Metal

Slag Arc Figure 7-14 Metal Inert Gas Arc Welding (MIG)

Atomic-Hydrogen

Base Metal

One of the highest temperature arc heating processes is also

Figure 7-12 Stick Rod Welding

a welding application. The atomic-hydrogen cycle produces

base metal temperatures as high as 6000 F. An arc is formed

between two tungsten electrodes. Hydrogen is flowed

Tungsten Inert Gas (TIG) through the arc. As the hydrogen passes through the heat of

the arc, it disassociates itself into singular atoms and absorbs

Tungsten inert gas welding uses a tungsten electrode to a great deal of energy. When the hydrogen leaves the arc, it

precipitate the arc to the base metal, as shown in Figure 7-13. A recombines and releases the stored energy in the form of

flow of inert gas, usually argon, is flowed around the arc to heat. Figure 7-15 shows an atomic-hydrogen arc welding

prevent inclusion of the atmosphere. The filler is added from process.

Shielding Gas Orifice

Ceramic Cup Tungsten

Electrode Tungsten Electrodes

Filler Rod Arc Arc

Weld Material Inert Gas Weld Material Hydrogen

Shield

Base Metal Base Metal

Figure 7-13 Tungsten Inert Gas Arc Welding (TIG) Figure 7-15 Atomic-Hydrogen Arc Welding