Page 166 - Electromechanical Devices and Components Illustrated Sourcebook

P. 166

128 Electromechanical Devices & Components Illustrated Sourcebook

Uses for electrical heating are nearly as numerous as motor

applications. We find electrical heating elements wherever we

go. Our kitchens have toasters, stove tops, crock pots, coffee

makers, and various other appliances, all with electrical heat-

Schematic Symbol

ing elements. Our hair dryers and curlers have electrical heat-

ing elements. Many of our hot water heaters and home heating

systems rely on electrical heating. Just by looking around as Protective Lip

you go through your day-to-day life, you’ll see hundreds of

electrical heating applications.

Most heating elements are resistive in nature. That is to say

Coiled Ni-Chrome Element

that the heating element represents a high-power resistor.

When a current is passed through the element, it glows red hot

and emits heat. Figure 7-1 shows a typical ribbon-type heat-

ing element. The unit is constructed with two threaded rods

that pinch a series of ceramic insulators into a column. The

two columns are separated by a ceramic frame. The element

is a nickle-chromium (Ni-Chrome) ribbon that is wound

Ceramic Coil Form

around the insulators. The ends of the ribbon are terminated

at the clamp rods, which also serve as the terminals.

Screw Base

Figure 7-2 Screw-in Heater Element

Schematic Symbol

Ceramic Insulators

Terminal

Ni-Chrome

Ribbon Schematic Symbol

Ceramic

Frame Coiled Ni-Chrome Element

Terminals

Terminal Clamp Bolts

Figure 7-1 Ribbon Heater Element

High-Temperature Board

Figure 7-3 Coiled Heater Element

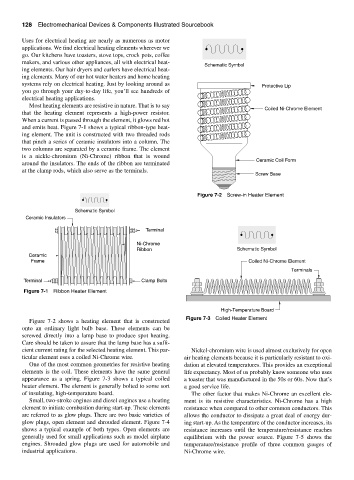

Figure 7-2 shows a heating element that is constructed

onto an ordinary light bulb base. These elements can be

screwed directly into a lamp base to produce spot heating.

Care should be taken to assure that the lamp base has a suffi-

cient current rating for the selected heating element. This par- Nickel-chromium wire is used almost exclusively for open

ticular element uses a coiled Ni-Chrome wire. air heating elements because it is particularly resistant to oxi-

One of the most common geometries for resistive heating dation at elevated temperatures. This provides an exceptional

elements is the coil. These elements have the same general life expectancy. Most of us probably know someone who uses

appearance as a spring. Figure 7-3 shows a typical coiled a toaster that was manufactured in the 50s or 60s. Now that’s

heater element. The element is generally bolted to some sort a good service life.

of insulating, high-temperature board. The other factor that makes Ni-Chrome an excellent ele-

Small, two-stroke engines and diesel engines use a heating ment is its resistive characteristics. Ni-Chrome has a high

element to initiate combustion during start-up. These elements resistance when compared to other common conductors. This

are referred to as glow plugs. There are two basic varieties of allows the conductor to dissipate a great deal of energy dur-

glow plugs, open element and shrouded element. Figure 7-4 ing start-up. As the temperature of the conductor increases, its

shows a typical example of both types. Open elements are resistance increases until the temperature/resistance reaches

generally used for small applications such as model airplane equilibrium with the power source. Figure 7-5 shows the

engines. Shrouded glow plugs are used for automobile and temperature/resistance profile of three common gauges of

industrial applications. Ni-Chrome wire.