Page 214 - Electromechanical Devices and Components Illustrated Sourcebook

P. 214

176 Electromechanical Devices & Components Illustrated Sourcebook

Joining wires is a necessity in almost any wiring harness. Wire Bundle

Standard crimp connectors can be used for this application, Wire Netting

but the preferred method is to splice and solder the wires and

protect them as shown in Figure 10-20. After the wires are

soldered and the flux is thoroughly cleaned off, a piece of heat

shrink is slid over the splice. The heat shrink is then heated

causing it to shrink tightly around the joint.

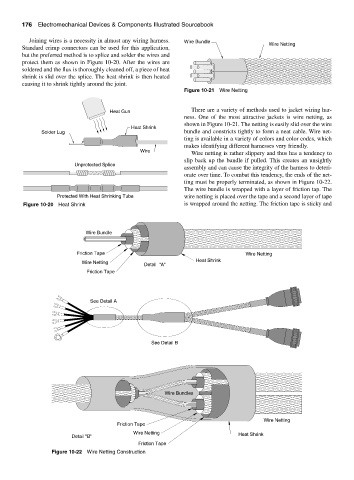

Figure 10-21 Wire Netting

There are a variety of methods used to jacket wiring har-

Heat Gun

ness. One of the most attractive jackets is wire netting, as

shown in Figure 10-21. The netting is easily slid over the wire

Heat Shrink

Solder Lug bundle and constricts tightly to form a neat cable. Wire net-

ting is available in a variety of colors and color codes, which

makes identifying different harnesses very friendly.

Wire

Wire netting is rather slippery and thus has a tendency to

slip back up the bundle if pulled. This creates an unsightly

Unprotected Splice

assembly and can cause the integrity of the harness to deteri-

orate over time. To combat this tendency, the ends of the net-

ting must be properly terminated, as shown in Figure 10-22.

The wire bundle is wrapped with a layer of friction tap. The

Protected With Heat Shrinking Tube wire netting is placed over the tape and a second layer of tape

Figure 10-20 Heat Shrink is wrapped around the netting. The friction tape is sticky and

Wire Bundle

Friction Tape Wire Netting

Heat Shrink

Wire Netting

Detail "A"

Friction Tape

See Detail A

See Detail B

Wire Bundles

Wire Netting

Friction Tape

Wire Netting Heat Shrink

Detail "B"

Friction Tape

Figure 10-22 Wire Netting Construction