Page 215 - Electromechanical Devices and Components Illustrated Sourcebook

P. 215

Chapter 10 Wire and Conductors 177

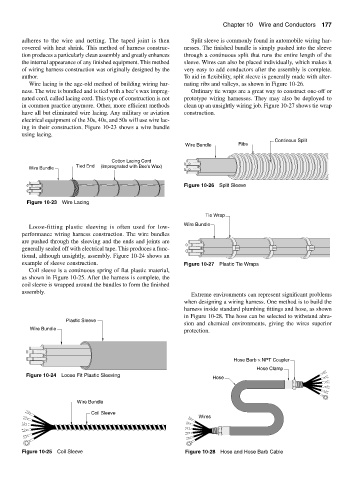

adheres to the wire and netting. The taped joint is then Split sleeve is commonly found in automobile wiring har-

covered with heat shrink. This method of harness construc- nesses. The finished bundle is simply pushed into the sleeve

tion produces a particularly clean assembly and greatly enhances through a continuous split that runs the entire length of the

the internal appearance of any finished equipment. This method sleeve. Wires can also be placed individually, which makes it

of wiring harness construction was originally designed by the very easy to add conductors after the assembly is complete.

author. To aid in flexibility, split sleeve is generally made with alter-

Wire lacing is the age-old method of building wiring har- nating ribs and valleys, as shown in Figure 10-26.

ness. The wire is bundled and is tied with a bee’s wax impreg- Ordinary tie wraps are a great way to construct one-off or

nated cord, called lacing cord. This type of construction is not prototype wiring harnesses. They may also be deployed to

in common practice anymore. Other, more efficient methods clean up an unsightly wiring job. Figure 10-27 shows tie wrap

have all but eliminated wire lacing. Any military or aviation construction.

electrical equipment of the 30s, 40s, and 50s will use wire lac-

ing in their construction. Figure 10-23 shows a wire bundle

using lacing.

Continous Split

Wire Bundle Ribs

Cotton Lacing Cord

Tied End (Impregnated with Bee's Wax)

Wire Bundle

Figure 10-26 Split Sleeve

Figure 10-23 Wire Lacing

Tie Wrap

Wire Bundle

Loose-fitting plastic sleeving is often used for low-

performance wiring harness construction. The wire bundles

are pushed through the sleeving and the ends and joints are

generally sealed off with electrical tape. This produces a func-

tional, although unsightly, assembly. Figure 10-24 shows an

example of sleeve construction. Figure 10-27 Plastic Tie Wraps

Coil sleeve is a continuous spring of flat plastic material,

as shown in Figure 10-25. After the harness is complete, the

coil sleeve is wrapped around the bundles to form the finished

assembly.

Extreme environments can represent significant problems

when designing a wiring harness. One method is to build the

harness inside standard plumbing fittings and hose, as shown

in Figure 10-28. The hose can be selected to withstand abra-

Plastic Sleeve

sion and chemical environments, giving the wires superior

Wire Bundle protection.

Hose Barb × NPT Coupler

Hose Clamp

Figure 10-24 Loose Fit Plastic Sleeving

Hose

Wire Bundle

Coil Sleeve

Wires

Figure 10-25 Coil Sleeve Figure 10-28 Hose and Hose Barb Cable